F97

Description

Originally targetted as a mid temperature off-white porcelainous stoneware. How it actually fires as a high temperature stoneware. Contains more than 60% OM4 ball clay, 20% PV clay (a plastic feldspar), 6% talc and 10% F65 silica sand. This fires off-white with almost no speckling, combining porcelain-like glaze effects with strong working properties of stoneware.

Process Properties

F97 feels very smooth on throwing (even though it contains a significant amount of fine silica sand). As a high ball clay body, it generates slip very well and has superior throwing characteristics even when comparatively soft. F97 will appeal to people who like a 'slick' responsive feel with a little tactile feedback.

Firing

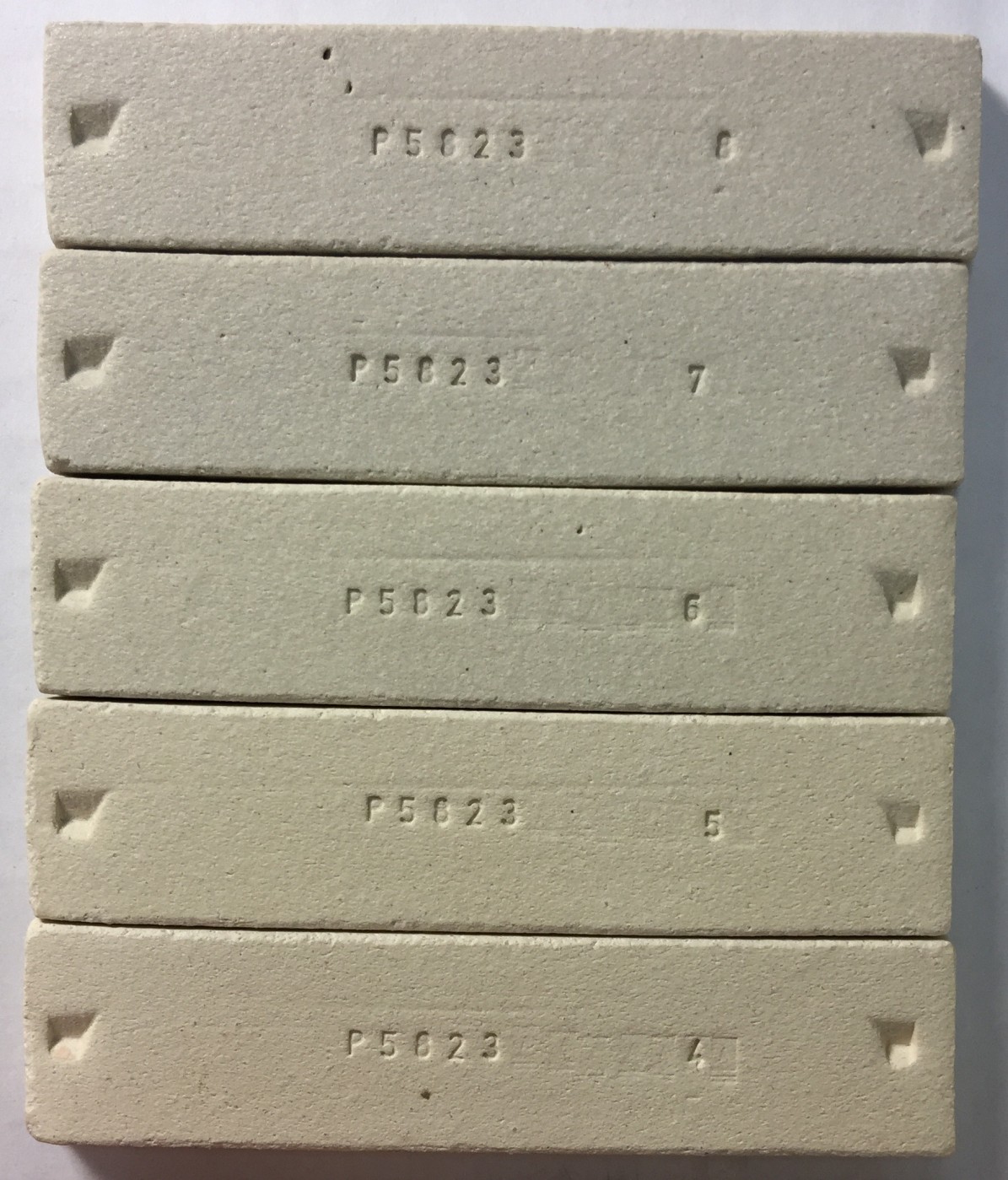

Fired bars are a nice dense grey buff cone 7-9. Below that they are buff coloured. At cone 8 the silica sand imposes a texture on the fired surface.

Because F97 contains significant silica sand we recommend that you exercise care when firing it through quartz inversion.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 4.5-5.5% Dry Strength: n/a Drying Factor: A000-B110 Dry Density: 1.95

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0.0-0.6% 48-65 (300-210 microns): 0.4-0.8 65-100 (210-149 microns): 2.5-3.5 100-150 (149-106 microns): 2.0-3.0 150-200 (106-75 microns): 5.5-7.5 200-325 (75-45 microns): 7.0-10.0

Fired Shrinkage:

Cone 6: 5.5-6.5% Cone 7: 6.0-7.0 Cone 8: 6.0-7.0 Cone 10: 6.0-7.0

Fired Absorption:

Cone 6: 2.5-3.5% Cone 7: 1.5-2.5 Cone 8: 1-2 Cone 10: 0.5-1.5