If we demand clay bodies with great working properties, why do we not demand the same of our glazes?

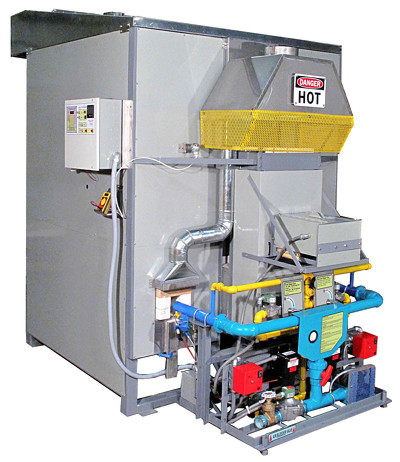

Computer controlled gas kilns are less expensive than in the past. There is no better way to start serious production of high quality ware.

Glorious Cone 10R Using Ravenscrag Slip!

Are you serious about the production of high quality ware? Nothing beats cone 10R! It is good for quality and business.

- Native materials: Glazes melt so much easier, so you can use raw and native glaze materials (gone are frits, borates and other low-melting and expensive materials). Ravenscrag and Alberta slip melt by themselves at cone 10.

- Quality: Porcelainous and white stoneware bodies are so strong and the glazes have higher silica and alumina so they are harder.

- Porcelain and whitewares fire blue-white instead of yellowy-white.

- It is the home of the most magic oxide in ceramics: iron. Only at Cone 10 reduction is iron a powerful glaze flux, variegator and crystalizer, a colorant of many characters in bodies and glazes and a speckling agent like no other. And it is safe and cheap!

- Cone 10 raw flux-sourcing materials are much less toxic.

- Cone 10 bodies can have higher clay content, and therefore be more plastic (because less feldspar is needed). Glazes also need less flux so more clay in the recipe means better suspension and hardening.

- The easiest mechanism to produce mattes lives at cone 10. Trying to crowbar magnesia or dolomite mattes lower using fluxes like boron glosses them, and the incredible soft silky surface is lost. Other lower fire matte mechanisms are fragile and trouble prone.

- There is no aesthetic that can match cone 10R in porcelain or stoneware.

- Firing consistency and cost: There are no kiln elements that deteriorate over time and fire slower, an old kiln fires the same schedule as a new one. Gas is cheaper than electricity and gas kilns can fire alot faster and this can more than compensate for the higher temperature (in industry fires are measured in minutes, not hours).

- There is much less crazing at cone 10 because the glazes, by necessity, have much less high expansion fluxes and more low expansion silica and alumina.

- There is little need to rely on complicated flux interactions to make things melt, the temperature does it all. There is a closer relationship between what the glaze chemistry suggests will happen in the kiln and what actually does happen. .

Here is what you need:

- A good automatic firing cone 10R kiln.

- Make your glazes from Ravenscrag and Alberta Slip so you only need to stock a minimum of materials.

- Plainsman clay bodies: No one on the planet makes better cone 10R native stonewares.

Glaze Recipes

Ravenscrag by itself fires to an excellent cone 10 glaze, especially as a silky matte base.

For functional glaze, consider testing for leaching, crazing and cutlery marking.

Courtesy of Digitalfire Reference LibraryAlberta Slip:Ravenscrag Cone 10R Celadon

Code: GR10-E

A celadon recipe affording slurry and fired properties control (because proportions of raw and calcined materials and frit can be adjusted)

| Alberta Slip 1000F Roast | 47.50 |

| Ravenscrag Slip | 47.50 |

| Ferro Frit 3134 | 5.00 |

| 100.00 |

This is a celadon that you can tune to your needs. It works well on dark and light stonewares and porcelains. Adjust the proportions of Alberta Slip to Ravenscrag Slip to fine-tune the color (more Ravenscrag for lighter color). Adjust the amount of frit to tune the amount of gloss and melt fluidity. Fine tune the thermal expansion by changing the frit (e.g. frit 3134 for higher expansion, 3249 for lower, 3124 for nuetral).

Since this glaze is 90% clay, roast half of the Alberta Slip complement to reduce the drying shrinkage (for application to bisque ware). If applied to leather-hard ware it should be OK as to use raw Alberta and Ravencrag Slips.

GR10-E Ravenscrag:Alberta Slip with 10% calcium carbonate

At cone 10R this produces an overly melted glaze. It also crazes.

Ravenscrag GR10-E celadon glaze

(50:50 Ravenscrag Slip:Alberta Slip) at cone 10R on porcelain (right) and stoneware (left).

GR10-E 50:50 Alberta Slip:Ravenscrag Slip celadon at cone 10R

On a white stoneware and a porcelain. The glaze is transparent, it has depth and varies in shade according to thickness, breaking to a much lighter shade on the edges of contours.

Ravenscrag Alberta Slip Celadon mug by Tony Hansen

The outside glaze on this cone 10R mug (made of Plainsman H550) is G2881B, simply an Alberta Slip:Ravenscrag Slip 50:50 mix (the Ravenscrag Slip portion was roasted). 5% Ferro Frit 3134 was added to get a little better melting (to produce a high gloss). This produces a good celadon with great working and application properties. Inside glaze: Pure Ravenscrag Slip (mixed 50:50 roast and raw).

Roasting Alberta and Ravenscrag Slips at 1000F: Essential for good glazes

Roasted Alberta Slip (right) and raw powder (left). These are thin-walled 5 inch cast bowls, each holds about 1 kg. I hold the kiln at 1000F for 30 minutes. Why do this? Because Alberta Slip is a clay, it shrinks on drying (if used raw the GA6-B and similar recipes will crack as they dry and then crawl during firing). Roasting eliminates that. Calcining to 1850F sinters some particles together (creating a gritty material) while roasting to 1000F produces a smooth, fluffy powder. Technically, Alberta Slip losses 3% of its weight on roasting so I should use 3% less than a recipe calls for. But I often just swap them gram-for-gram.

Pure Ravenscrag Slip

Code: GR10-A

Ravenscrag all by itself makes a great cone 10 reduction semi-gloss glaze. It also has great working properties.

| Ravenscrag Slip 1000F Roast | 50.00 |

| Ravenscrag Slip | 50.00 |

| 100.00 |

Ravenscrag Slip is a revolutionary glaze material for stoneware. At cone 10R it can be used pure and produces a functional semi-gloss surface. The possibilities are endless on what you can do by adding things to this base material. You can make additions to gloss it or matte it more, color and variegate it and/or opacify it. Most will contain 90% Ravenscrag (you can make bamboo, tenmoku, celadon, iron crystal, white, matte, glossy, and much more).

Ravenscrag Slip is a clay, so it shrinks. We recommend starting a 50:50 raw:roast mix in recipes that call for a high percentage of the material (use the roast instructions at http://ravenscrag.com). Adjust the proportion to get the fastest drying possible while still drying hard and having good slurry suspension. Ravenscrag glazes resist settling in the bucket and go on even (when mixed correctly).

Glazes having a high percentage of Ravenscrag Slip are most often prepared using the traditional method of simply adding water until the preferred viscosity is achieved (the material has inherent properties that produce functional slurries for dipping). Control of drying shrinkage and slurry character is achieved by varying the proportion roast and raw powder in the recipe. For us, a weight ratio of 88 water to 100 powder (2200 tap water for 2.5kg of powder) produces a creamy slurry that gives the right thickness on 1-2 second dip on 1850F bisque-ware (with minimal dripping), it has 1.45-1.47-specific-gravity. Using your water you will likely find some variation in this. This recipe actually does not respond to flocculant additions that gel traditional mineral-blend glazes to a thixotropic state.

3000 grams of powder mix makes about 1 Canadian gallon.

Roast or calcine your Ravenscrag Slip (or other clays) for much better results

Calcined or roasted clays are indispensable in making many types of glazes, they reduce drying shrinkage (and thus cracking and crawling) compared to those made using raw clay. In a glaze, you can fine-tune a mix of raw and roast clay to achieve a compromise between dry hardness and low shrinkage. This is Ravenscrag Slip, we roast it to 1000F (roasting is adequate to destroy plasticity and produces a smoother powder than calcining at higher temperatures). To make sure the heat penetrates for this size vessel I hold it for 2 hours at 1000F. Calcined koalin is getting harder to find, this same process can be used to make your own from a raw kaolin powder. One thing is worth noting: Weight lost on firing actually means that less of the roasted powder is needed to yield the same amount of material to the glaze melt, it can be anywhere from 5-12% less.

Sterile white vs. pure Ravenscrag Slip as a liner glaze at cone 10R

This picture does not fully convey how much better the Ravenscrag is as a liner glaze (vs. G1947U). It has depth and looks much richer. It course, it could be opacified somewhat to be whiter and would still retain the surface quality (as long is it is not too opaque). The body is Plainsman H450. The outside glaze is pure Alberta Slip.

G1947U transparent glaze (left) vs. Ravenscrag Slip at cone 10R

Ravenscrag Slip is not ultra glossy but has a silky surface. It also contains some iron oxide and this colors the glaze somewhat. But the surface is much less sterile and pleasant to touch.

Laguna B-Mix, B-Mix+Fireclay with Ravenscrag GR10-A, GR10-C glazes

Left two mugs are glazed with pure Ravenscrag Slip (roast:raw combo), far right one is RavenTalc silky matte (GR10-C). The speckled mugs have 10% of a Plainsman Fire-Red (a blend of a red fireclay, M2 and a heavily speckled ball clay). Ravenscrag Slip is an ideal base for cone 10R glazes, so many glazes can be made by adding pigments, opacifiers, variegators and matting agents.

Laguna B-Mix Cone 10R mugs with Alberta and Ravenscrag glazes

B-Mix is a popular high-ball clay very plastic grey cone 10R stoneware in North America. The two mugs on the left have pure Ravenscrag Slip on the inside (the middle on the outside also), it fires almost transparent with a slightly silky surface. Pure Alberta Slip is employed on the outside of the left one and the inside of the right one. The outside of the right one is RavenTalc silky matte. In all cases the Ravenscrag and Alberta Slip are mixed half-and-half calcined and raw. B-Mix fires dark enough and with enough specks that a normal transparent glaze is not very interesting. But these Ravenscrag ones look much better (for use as a liner glaze).

Ravenscrag Slip pure: Oxidation vs. Reduction

Pure Ravenscrag Slip on a porcelain at cone 10 oxidation (left) and cone 10 reduction (right). The reduction fired sample is a very smooth pleasant semi-matte, the other is glossier but dimpled.

2, 5, 10 and 15% calcined alumina added to Ravenscrag Slip

The Ravenscag:Alumina mix was applied to a buff stoneware fired at cone 10R (by Kat Valenzuela). Matting begins at only 5% producing a very dry surface by 15%. This "psuedo matte" surface is simply a product of the refractory nature of the alumina as a material, it does not disassociate in the melt to yield its Al2O3 as an oxide (as would a feldspar, frit or clay). The same test using alumina hydrate demonstrates that it disassociates somewhat better (although not completely).

2, 5, 10 and 15% alumina hydrate added to Ravenscrag Slip

Pure Ravenscrag Slip is glaze-like by itself (thus tolerating the alumina addition while still melting as a glaze). It was applied on a buff stoneware which was then fired at cone 10R (by Kat Valenzuela). This same test was done using equal additions of calcined alumina. The results suggest that the hydrated version is decomposing to yield some of its Al2O3, as an oxide, to the glaze melt. By 15% it is matting and producing a silky surface. However crazing also starts at 10%. The more Al2O3 added the lower the glaze expansion should be, so why is this happening? It appears that the disassociation is not complete, raw material remains to impose its high expansion.

2, 5, 10, 15% dolomite added to Ravenscrag Slip at cone 10R

This is a buff stoneware clay. Crystal development toward a dolomite matte begins at 15%. By Kat Valenzuela.

How to matte Ravenscrag Slip at cone 10 by adding talc

2,5,10,15% talc added to Ravenscrag Slip on a buff stoneware fired at cone 10R. Matting begins at 10%. By Kat Valenzuela.

CaO is a strong flux but it can cause crazing

2, 5, 10, 15% calcium carbonate added to Ravenscrag Slip on a buff stoneware fired at cone 10R. It gets progressively glossier toward 15%, crazing starts at 10% (test by Kat Valenzuela). Adding a flux only reduces the SiO2 and Al2O3, this pushes the thermal expansion upwards. 5% is actually sufficient. An alternative would be to use wollastonite, it supplies SiO2 also.

100% Ravenscrag slip on Plainsman H550 stoneware fired to cone 10R

The surface is between silky and glossy.

B-Mix with Ravenscrag Slip inside and Alberta Slip outside

Fired cone 10R. The one on the right contains 10% of Plainsman A1:St Rose Red mix to add speckle.

Ravenscrag Cone 10R Bamboo Matte

Code: GR10-J1

Plainsman Cone 10R Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com.

| Ravenscrag Slip | 51.60 |

| Dolomite | 12.10 |

| Talc | 2.60 |

| Gerstley Borate | 4.00 |

| Calcined Kaolin | 13.50 |

| Custer Feldspar | 16.20 |

| Add | |

| Red Iron Oxide | 1.00 |

| 101.00 | |

This is GR10-J dolomite matte (a Ravenscrag version of G2571A) with 1% iron oxide added (to produce a bamboo effect).

An alternative bamboo (for both this and the G2571A recipe) is to add 3.5% rutile and 10% zircopax.

How to turn a dolomite matte white glaze into a bamboo matte

Make cone 10R bamboo colors using the GR10-J Ravenscrag silky matte base recipe (right) and adding 1% iron (left), (0.5% centre). These samples are porcelain. This iron addition also works using the G2571A matte base recipe.

Ravenscrag GR10-J Cone 10R Bamboo glaze variation

Porcelain (left), buff stoneware (center), iron stoneware (right). Works well on all body types. On porcelain, interesting red tones and variations in tone appear.

Bamboo glaze that is actually functional

The stunning cone 10R Ravenscrag bamboo glaze (it is GR10-J plus 0.5% iron oxide) on a Grolleg porcelain. Up close it can feel and look like a fine wood surface (when used on a porcelain).

Two G2571A Bamboo versions: With iron, rutile-zircopax

These mugs are Plainsman H450 fired at cone 10R. Both have a black engobe (L3954N) applied to the insides and half way down the outside during leather hard stage (the insides are glazed with Ravenscrag silky matte and G1947U over the black engobe). The bamboo glazes can thus be seen over the black (upper half) and the raw buff body (lower). The bamboo glaze on the left has 1% iron added to the base G2571A recipe. The one on the right has 3.5% powdered rutile and 10% zircopax added.

The bamboo matte on the left is better: It does not stain and does not craze.

These mugs are Plainsman H443. The cone 10R dolomite matte bamboo glaze on the left (A) has 3.5% rutile and 10% Zircopax added to our base G2571A dolomite matte. The one on the right (B) has the same addition but in a base having less CaO/MgO and much more KNaO. This gives it a craze-prone calculated thermal expansion of 7.9 (vs 6.7 for ours). B also stains badly (as can be seen from the felt marker residue that could not be removed using lacquer thinner). Why does A stain only slightly? It has an additional 4% Gerstley Borate, a powerful flux that develops the glass surface better (giving a slightly less matte surface).

Ravenscrag Cone 10R Dolomite Matte

Code: GR10-J

Plainsman Cone 10R Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com.

| Ravenscrag Slip | 51.60 |

| Dolomite | 12.10 |

| Talc | 2.60 |

| Gerstley Borate | 4.00 |

| Calcined Kaolin | 13.50 |

| Custer Feldspar | 16.20 |

| 100.00 |

This is the classic cone 10 reduction silky white matte, its feel, beauty and utility are very difficult to match in any other system. Unlike many feldspar saturated dolomite mattes in use, this one does not craze on stonewares and it does not cutlery mark or stain.

This glaze was developed from the popular G2571A, it has the same chemistry however it sources that chemistry from a completely different recipe based on Ravenscrag Slip (this is a good example of how Insight ceramic chemistry software can be used). The pleasant silky surface is almost identical (though slightly darker in color due to a little higher iron content). Add a little zircopax (e.g. 3-5%) to whiten the color if you desire or if you need to precisely match the G2571A. This glaze has the characteristic superb application and suspending properties of Ravenscrag Slip glazes.

Note that the calcined kaolin is important. If you use raw kaolin, the glaze will shrink too much during drying. For a slip glaze, raw kaolin would be OK. If you do not have the Boraq (Gerstley Borate substitute) then you can substitute real Gerstley Borate or another equivalent.

The two most common variations are bamboo and robin's egg blue (see photos here).

Mar 2015: We have found a tendency for this glaze to craze on some stonewares after decal firings. See the linked picture.

Duplicating the G2571A dolomite matte using a Ravenscrag Slip based recipe

GR10-J Ravenscrag silky matte (right) and G2571A matte (left) on a dark burning iron speckled stoneware at cone 10R. The surfaces have identical feel (the chemistries are very close). The former fires a little darker color because of the iron contributed by the Ravenscrag Slip.

A refined-material cone 10R dolomite matte (left) vs. one made using Ravenscrag Slip

GR10-J Ravenscrag silky matte (right) and G2571A matte (left) on a buff stoneware at cone 10R. Surfaces feel identical, the slightly darker color is due to iron content in the Ravenscrag. The former was formulated to mimic the latter using as much Ravenscrag Slip as possible yet still maintain the same chemistry.

Robin's egg blue at Cone 10R: add 1% cobalt oxide and 0.2% chrome oxide to GR10-J Ravenscrag silky matte. Does not work well on porcelains (left), very well on buff stonewares (right). Inside of center mug is GR10-J.

How to turn a dolomite matte white glaze into a bamboo matte

Make cone 10R bamboo colors using the GR10-J Ravenscrag silky matte base recipe (right) and adding 1% iron (left), (0.5% centre). These samples are porcelain. This iron addition also works using the G2571A matte base recipe.

Ravenscrag Slip based dolomite matte

GR10-J Ravenscrag dolomite matte base glaze at cone 10R on Plainsman H443 iron speckled clay (actually, the MgO is being sourced from talc instead of dolomite). This recipe was created by starting with the popular G2571 base recipe (googleable) and calculating a mix of materials having the maximum possible Ravenscrag Slip percentage. The resultant glaze has the same excellent surface properties (resistance to staining and cutlery marking) but has even better application and working properties. It is a little more tan in color because of the iron content of Ravenscrag Slip.

Ravenscrag Cone 10R Silky Talc Matte

Code: GR10-C

Just Ravenscrag Slip plus 10% talc produces a visually variegated surface that feels silky and looks stunning!

| Ravenscrag Slip Raw | 45.00 |

| Ravenscrag Slip 1000F Roast | 45.00 |

| Talc | 10.00 |

| 100.00 |

This glaze is more silky (less matte) than the GR10-J glaze, it is more beautiful visually and to the touch than a photo can convey. It works well on both buff and dark stonewares and even porcelain. It would also be an excellent base for the addition of a zircon opacifier and of colors.

For mixing instructions please see the notes for the base GR10-A recipe.

RavenTalc silky matte on the outside of a cone 10R buff stoneware mug

GR10-C Ravenscrag cone 10R silky matte glaze closeup (on Plainsman H550 stoneware). The recipe is 90% Ravenscrag Slip (roast:raw combo) and 10% talc. The inside of this piece just has pure Ravenscrag (raw:roast).

Laguna B-Mix, B-Mix+Fireclay with Ravenscrag GR10-A, GR10-C glazes

Left two mugs are glazed with pure Ravenscrag Slip (roast:raw combo), far right one is RavenTalc silky matte (GR10-C). The speckled mugs have 10% of a Plainsman Fire-Red (a blend of a red fireclay, M2 and a heavily speckled ball clay). Ravenscrag Slip is an ideal base for cone 10R glazes, so many glazes can be made by adding pigments, opacifiers, variegators and matting agents.

Difference between oxidation and reduction! GR10-C matte on Plainsman H443

Same body, same glaze. Left is cone 10 oxidation, right is cone 10 reduction. What a difference! This is a Ravenscrag-Slip-based recipe on a high-fire iron stoneware. In reduction, the iron oxide in the body and glaze darkens (especially the body) and melts much more. The behavior of the tin oxide opacifier is also much different (having very little opacifying effect in reduction).

Plainsman H435 with Ravenscrag Talc glaze matte inside, Ravenscrag Dolomite matte outside

Fired at cone 10R. The GR10-C Raven-Talc matte is just 90% Ravenscrag Slip and 10% talc. This produces a stunning silky, variegated surface (which could be a base for many colorants). The GR10-J Raven-Dolomite matte was patterned after our G2571A glaze, but using as much Ravenscrag Slip in the recipe as possible while maintaining the same chemistry (its surface is less variegated and more matte).

Laguna B-Mix Cone 10R mugs with Alberta and Ravenscrag glazes

B-Mix is a popular high-ball clay very plastic grey cone 10R stoneware in North America. The two mugs on the left have pure Ravenscrag Slip on the inside (the middle on the outside also), it fires almost transparent with a slightly silky surface. Pure Alberta Slip is employed on the outside of the left one and the inside of the right one. The outside of the right one is RavenTalc silky matte. In all cases the Ravenscrag and Alberta Slip are mixed half-and-half calcined and raw. B-Mix fires dark enough and with enough specks that a normal transparent glaze is not very interesting. But these Ravenscrag ones look much better (for use as a liner glaze).

Transparent and RavenTalc silky matte glazes on black engobe at cone 10R

Clay is Plainsman H450. The L3954N black engobe was applied at leather hard stage (on the insides and partway down the outside). The G1947U clear glossy glaze over it on the inside produces a deep and vibrant hue (left). The inside glaze on the right is GR10-C Ravenscrag silky matte. The outsides are GR10-J Ravenscrag Dolomite matte with a little added cobalt and iron (for blue and brown).

Ravenscrag Slip + 10% talc = fantastic cone 10R silky matte glaze

The clays are Plainsman H450 and H550. Firing is cone 10 reduction. A 50:50 mix of roasted and raw Ravenscrag slip was used. L3954N black engobe was applied at leather hard stage (on the insides and partway down the outsides). We call this recipe GR10-C Ravenscrag Talc Matte, it is on the insides of both and on the outside of the one on the left. The outside of the other is G2571A Bamboo, it is also an excellent matte base. The silky matte surfaces produced by these two are both functional (they are very durable and do not stain or cutlery mark). And they are very pleasant to the touch.

Ravenscrag Cone 10R Tenmoku

Code: GR10-K1

Plainsman Cone 10R Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com.

| Ravenscrag Slip | 95.00 |

| Calcium Carbonate | 5.00 |

| Add | |

| Red Iron Oxide | 10.00 |

| 110.00 | |

Like a typical tenmoku, this fires to a brilliant deep gloss that will run if applied too thickly. It appears best on porcelain on white stoneware. Tiny iron silicate crystals grow on the surface (depending on the speed of cooling).

Adjust the calcium carbonate to fine tune the degree of melting.

Tenmokus made from Alberta Slip and Ravenscrag Slip

GR10-K1 Cone 10R Ravenscrag Tenmoku (right) compared to Tenmoku made from Alberta Slip (left, it is 91% Alberta Slip with 5% added calcium carbonate and 2% iron oxide). Left is Plainsman P700 porcelain, right is H570. Tenmokus are popular for the way they break to a crystalline light brown on the edges of contours.

Compare Ravenscrag and Alberta Slip tenmokus at cone 10R

GR10-K1 Ravenscrag tenmoku (left) compared to Alberta Slip tenmoku GA10-B (center) and pure Alberta Slip (right).

Add 5% calcium carbonate to a tenmoku. What happens?

In the glaze on the left (90% Ravenscrag Slip and 10% iron oxide) the iron is saturating the melt crystallizing out during cooling. GR10-K1, on the right, is the same glaze but with 5% added calcium carbonate. This addition is enough to keep most of the iron in solution through cooling, so it contributes to the super-gloss deep tenmoku effect instead of precipitating out.

Ravenscrag Iron Crystal

Code: GR10-L

Plainsman Cone 10R Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com.

| Ravenscrag Slip 1000F Roast | 0.00 |

| Ravenscrag Slip | 100.00 |

| Add | |

| Red Iron Oxide | 10.00 |

| 110.00 | |

Without any added flux Ravenscrag will produce an iron crystal surface with 10% iron oxide.

An iron crystal glaze on a buff stoneware at cone 10R

This iron crystal glaze is Ravenscrag slip plus 10% iron oxide fired to cone 10R on Plainsman H550. Since Ravenscrag slip is a glaze-by-itself at cone 10, it is an ideal base from which to make a wide range of glazes.

Fixing a crawling problem with Ravenscrag Tenmoku

Crawling of a cone 10R Ravenscrag Slip iron crystal glaze. The added iron oxide flocculates the slurry raising the water content, increasing the drying shrinkage. To solve this problem you can calcine part of the Ravenscrag Slip, that reduces the shrinkage.

A cone 10R iron crystal glaze using only Ravenscrag Slip and Iron

Ravenscrag Slip, by itself, produces a silky transparent glaze at cone 10R. It is an excellent base to which to add colorants and modifiers. This is a simple addition of 10% iron oxide (Ravenscrag Slip already contains 2% iron, making about 12% total Fe2O3). This GR10-L recipe produces a stunning crystalline fired surface on these two porcelains. This "beyond-tenmoku" effect happens because of the extra iron and a slow cooling rate. The 12% iron dissolves in the glaze melt during heat up in the firing, but during cooling, the extra 2% precipitates out to produce these surfaces. The iron also acts as a flux in reduction firing, greatly increasing melt fluidity. Take that last statement seriously: The iron is a flux and the glaze will melt much more (it can wreck your kiln shelves if it runs). That being said, Ravenscrag Slip is more melt-stable than other bases, making it a more stable host for the iron addition.