M2 Red Clay

Description

A pure clay that we dig straight out of the ground and grind into a powder. It matures in the kiln at higher temperatures than terra cotta but lower than stoneware (and the development of vitrification is not nearly as volatile as for terra cottas). It is a high iron, moderate plasticity, smooth, dark burning stoneware.

M2 is our most important iron-bearing material. It works so well because of its consistency, the fact that it does not increase body plasticity, its broad firing range, fine particle size, lack of soluble salts, purity (low particulate iron impurities) and its linear (rather than volatile) maturing curve. We have a number of customers that use M2 pure (without any additions).

Substitutes For

Terra Cotta clays, are by nature, variable, high in solubles salts, contaminated with troublesome things and they have a volatile firing curve. M2 is a very unique material in that it has none of the above problems. We can only think of a few other clays that would be possible substitutes.

Redart: M2 has less iron, yet it fires to a very similar color, but is much more plastic than Redart.

Lizella Clay: M2 has more iron, vitrifies at a much lower temperature and has a finer particle size. Lizella is not commonly available.

Process Properties

This is not as plastic as a typical pottery body, although it can be formed. In recipes it needs the help of ball clay and/or bentonite. A typical vitreous cone 6 recipe might be 80% M2 and 20% ball clay. Or 87% M2, 10% silica, 3% bentonite.

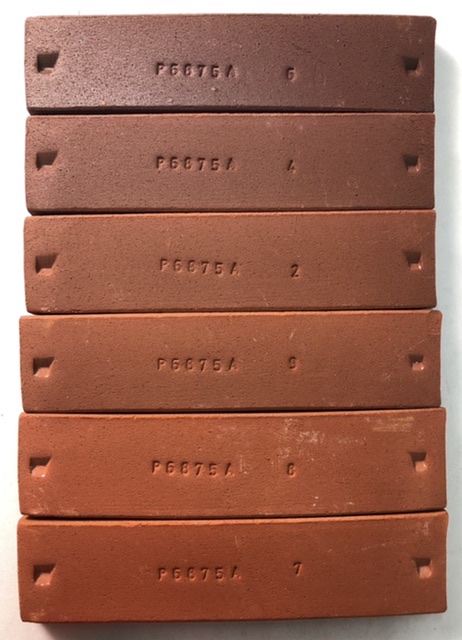

Firing

Used pure, M2 is over-fired by cone 6 (starting to melt), it develops best red color around cone 2. Since adding ball clays (which are refractory) moves both the maturity and plasticity in the right direction, and M2:Ball Clay mix will work well at cone 6. For the darkest colored bodies, M2 needs to be kept at a high percentage (so the lower ball clay will necessitate a little bentonite for plasticity).

Physical Properties

Drying Shrinkage: 6.0-7.0% Drying Factor: C120

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0.0-0.6% 48-65 (300-210 microns): 0.4-0.8 65-100 (210-149 microns): 2.5-3.5 100-150 (149-106 microns): 2.0-3.0 150-200 (106-75 microns): 5.5-7.5 200-325 (75-45 microns): 7.0-10.0

Fired Shrinkage:

Cone 2: 4.0-5.0% Cone 4: 4.5-5.5 Cone 6: Overfired

Fired Absorption:

Cone 2: 3.0-4.0% Cone 4: 1.0-2.0 Cone 6: Overfired

Chemical Analysis

CaO 0.3 K2O 2.7 MgO 1.0 Na2O 0.1 TiO2 0.7 Al2O3 13.5 P2O5 0.3 SiO2 69.4 Fe2O3 6.1 LOI 6.0%