Buffstone

Description

A general-purpose medium plasticity clay. If you are using clay with children the lower price of Buffstone and its utility may interest you. Firing is commonly done at cone 06-04 (usually with bottled underglazes and glazes).

Process Properties

Buffstone is pure A3, one of our native buff-color-burning stoneware materials. It contains a small amount of bentonite to improve plasticity and slow down drying. Its texture is somewhat sandy. Some plasticity is lost to the clay body when scrap clay is reconstituted, add more bentonite if needed (e.g. 1%). Extra drying precautions are appropriate for pieces of uneven thickness.

Firing

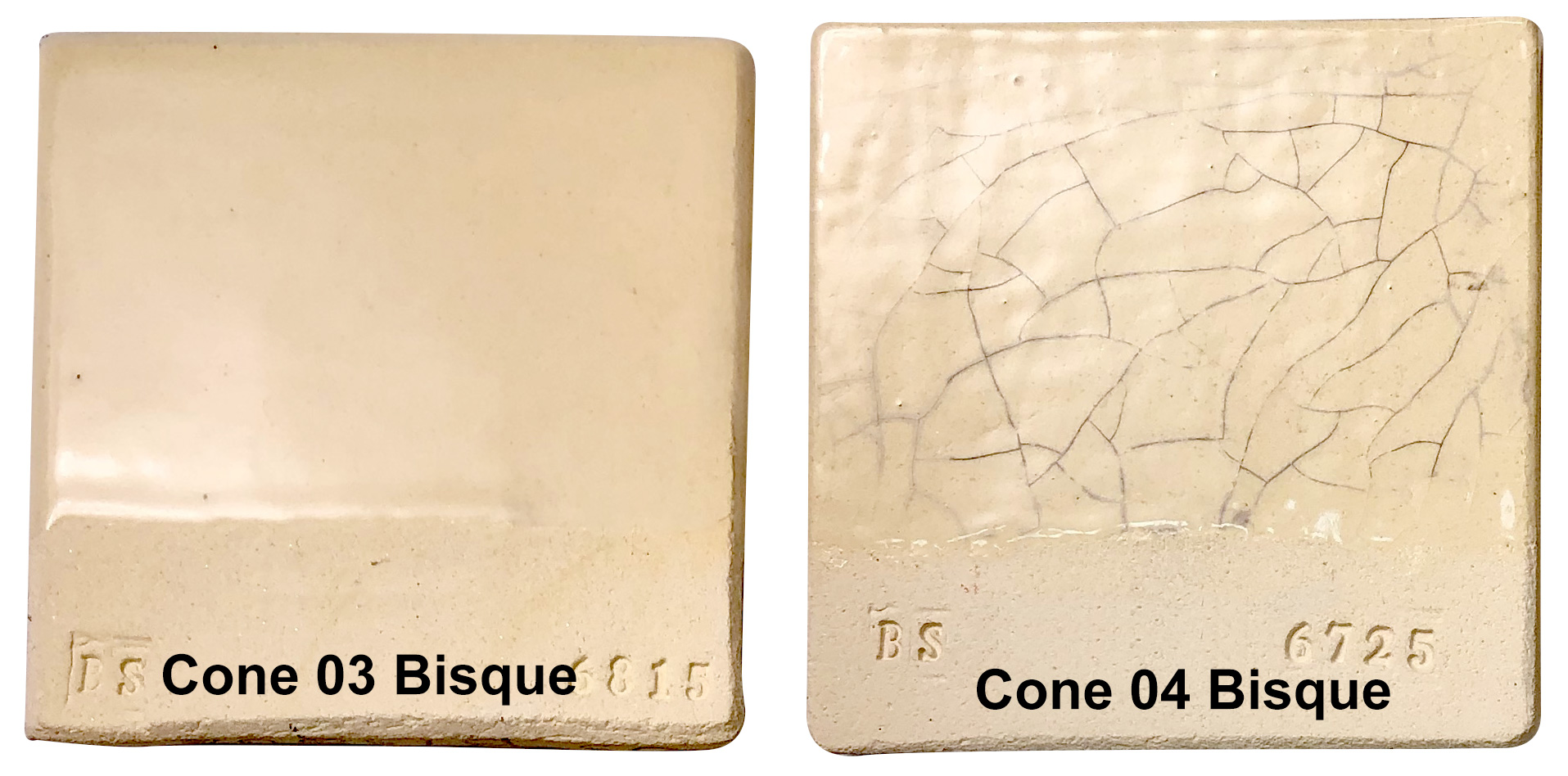

At cone 06 all buff and white burning clays fire to a porous matrix and have low strength (Buffstone is a little more porous than most). Notwithstanding this, cone 06 is convenient for schools and a wide array of commercial low-fire glazes are available for the making of decorative objects. Buffstone requires no special firing procedures if ware is completely dry. It will withstand kiln firings up to cone 10. For low fire glazing the higher you can bisque the stronger ware will be (we recommend cone 03 or 02).

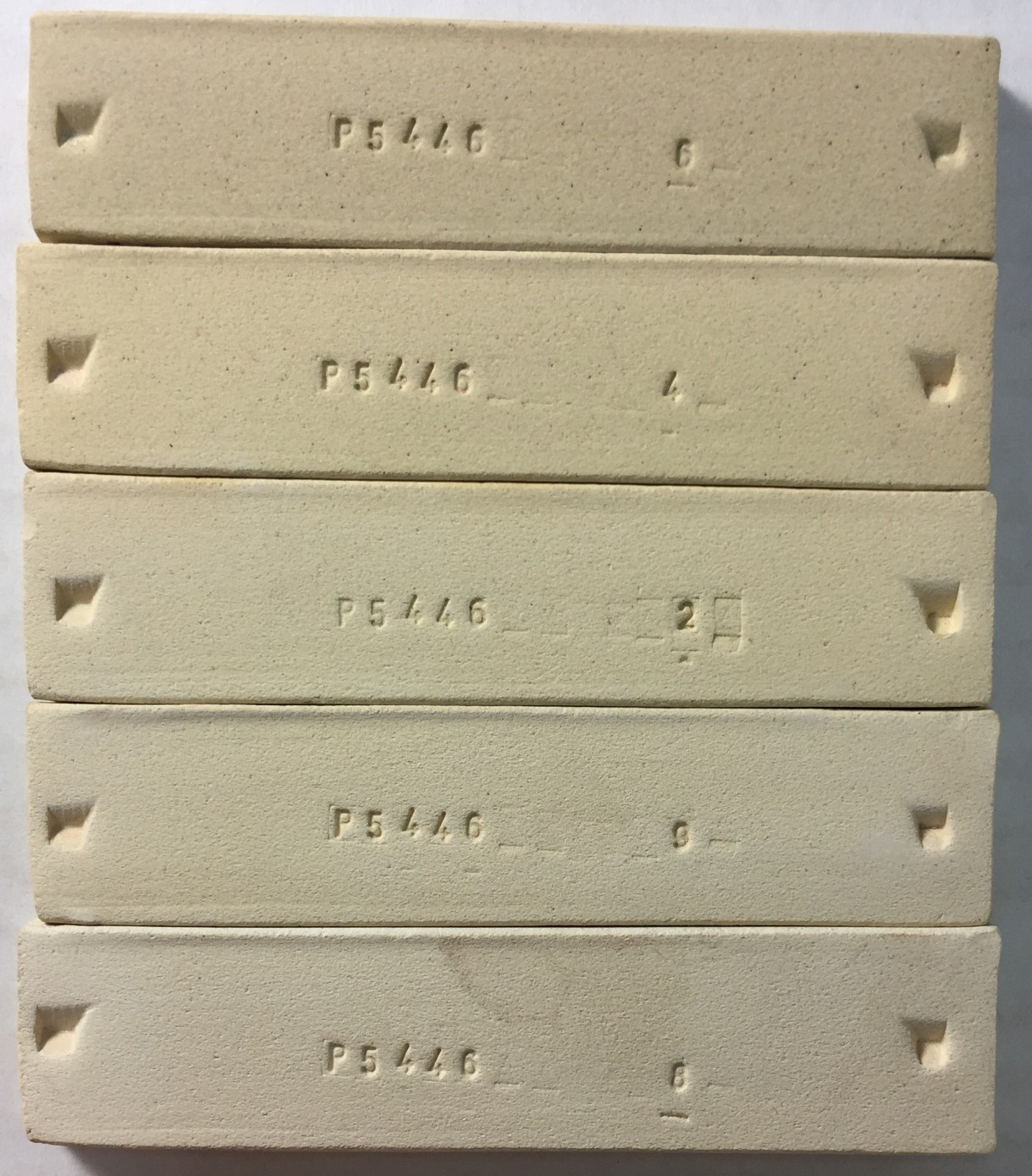

Buffstone fired bars. Cone 04, 02, 2, 4 and 6 oxidation (bottom to top). This spans the range of up to 14% porosity on the low end to near storeware density around cone 8 (representing a range of about 300 degrees F).

To get the best defect-free surface please consider using the drop-and-hold slow-cool 04DSDH firing schedule.

Glazing

Although Buffstone fits many commercial glazes out-of-the-kiln it will eventually craze most of them (e.g. Spectrum 700). Fit can be improved by bisque firing at cone 03. It is also possible to make your own glazes that will fit permanently (e.g. our G3879 or G1916Q recipes and their variations).

Using colored glazes is preferable to underglazes, especially with children. If you prefer the use of underglazes here are measures that will minimize the chances of them flaking off: Applied them at the leather-hard state. Avoid covering entire surfaces or putting them on too thick. Fluxes them to bond better, check here for an example.

Buffstone with G2931L glaze fired at cone 06. A hotter bisque not only produces a stronger body but also eliminates crazing (these specimens are one month old).

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

Physical Properties

Drying Shrinkage: 6.5% Dry Strength: n/a Water Content: 19.5-20.5% Drying Factor: C120

Sieve Analysis (Tyler mesh):

+65: 0.1-0.5% 100-150: 1.5-3.5 150-200: 3.5-5.5 200-325: 8.0-11.0

Fired Shrinkage:

Cone 04: 0.5% Cone 02: 1.5 Cone 2: 2.0 Cone 4: 2.5 Cone 6: 4.0

Fired Absorption:

Cone 04: ~14.0% Cone 02: ~12 Cone 2: ~10 Cone 4: ~9 Cone 6: ~6

Gallery

Buffstone and L215 with underglaze decoration and G2931 weigh-and-mix-yourself clear dipping glazes. But they are not the same. The G2931L glaze (left) has a lower thermal expansion (to slow crazing on Buffstone). The G2931K glaze fits L215 because the latter contains some talc (which raises its expansion). The L215 mug has survived a 300F-to-ice-water thermal shock without crazing or shivering. If you switch the glazes the Buffstone mug would craze it and the L215 would shiver it off in flakes.

Buffstone, L212 and L213. Each has its own clear glaze. G2931L, G2931K and G2931H.

L is low expansion (for zero-talc porous bodies like Buffstone). K is intermediate (for moderate-talc bodies like L215, Zero3 stoneware and porcelain). H is high-expansion (for higher-talc bodies like L212, L213).

Buffstone mug at cone 10R. Outside glaze is AlbertaSlip/Ravenscrag Celadon. The liner glaze is Ravenscrag plus 10% talc. Notice the foot ring has soluble salts that can stick ware to shelves, if you use this clay at cone 10R be sure to use kiln wash and grind the foot rings well after firing.