A3 Stoneware

Description

High temperature, medium plastic, sandy, vitreous, buff-white firing, clean burning native stoneware. A3 clay is mined from our Ravenscrag, Sask. quarry from a single clay seam (below A2 and above 3B). It provides the basis for most of our high-fire stoneware bodies. It fires vitreous enough to be used as-is for the production of cone 9-10 stoneware pottery.

Process Properties

From a workability point of view, A3 clay is suitable as a major ingredient in stoneware clay bodies. It is balanced enough that it can actually be the only ingredient in a cone 10 buffstone storeware.

A3 does not disperse or deflocculate. Soluble materials within the clay impede the action of normal deflocculants, resulting in gelling of the slurry.

A3 has the potential to make finer stoneware if it could be processed to 200 mesh and the coarser sand and iron stone concretion particles removed. This would also improve plasticity and the degree of vitrification it would tolerate.

Glazing

A3 stoneware is high in quartz and not difficult to fit glazes to, especially at higher temperatures. Having minimal impurities it will present few problems with regard to glaze pinholing.

Physical Properties

Drying Shrinkage: 1995 6.3-7.3%, 1999 6.0-7.0 Dry Strength: n/a Water Content: 22.0-23.0 Drying Factor: C130 Dry Density: n/a

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0-0.1% 48-65 (300-210 microns): 0.0-0.3 65-100 (210-149 microns): 0.2-0.8 100-150 (149-106 microns): 1.0-2.0 150-200 (106-75 microns): 1.0-3.0 200-325 (75-45 microns): 3.0-8.0

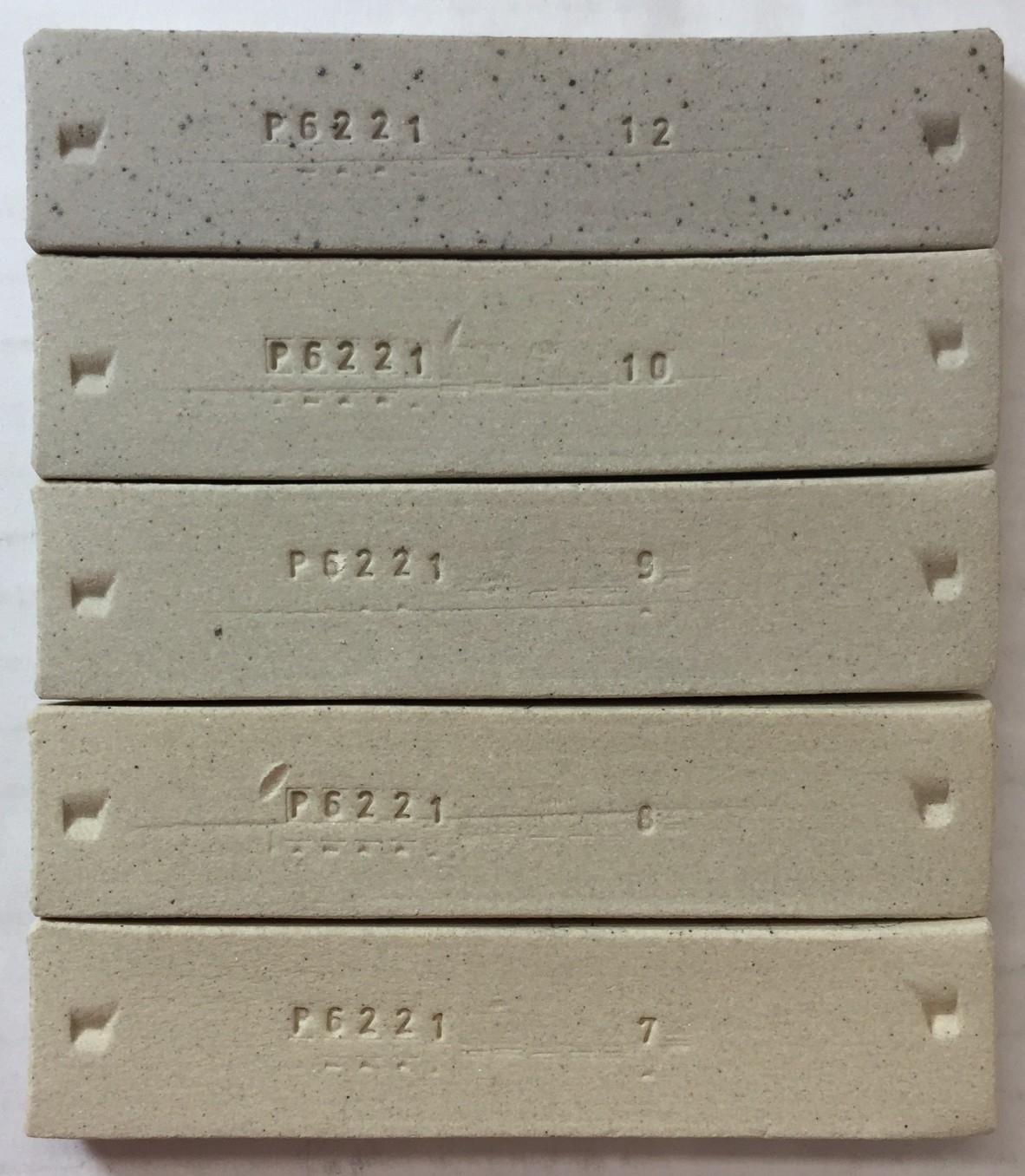

Fired Shrinkage:

1995 1999 Cone 6: 5.0-6.0% 4.0-5.0% Cone 8: 5.5-6.5 4.5-5.5 Cone 10: 6.0-7.0 5.5-6.0 Cone 10R: 6.0-7.0 6.0-7.0

Fired Absorption:

1995 1999 Cone 6: 1.0-2.0% 4.0-5.0% Cone 8: 0.5-1.5 2.5-3.5 Cone 10: 0.2-0.8 1.5-2.5 Cone 10R: 0.5-1.5 1.0-2.0