A2 Ball Clay

Description

A smooth and highly plastic, buff burning, refractory, coarse grained, lignitic ball clay. A2 is mined in Southern Saskatchewn and is both a ball clay and a fireclay. We have large reserves of this material. Ball clays are suitable in a wide range of ceramic and non-ceramic applications. When A2 is fine ground and impurities air-separated (which we do not currently do) it is very similar to commercial ball clays from the southern USA (although darker burning).

While kaolin is white and clean and considered pure clay mineral, ball clays, by comparison, are generally grey or brownish in color and differ in the following ways:

- They have a much finer ultimate particle size

- They contain organic material, especially lignite, that darken the raw color

- They are much more plastic and suspend better

- They contain chemical impurities that darken fired color (especially iron oxide)

- They melt at a lower temperature.

- Ultra-fine particle size: Ultimate particles can be 0.2 microns

- Flat-shaped aluminum-silicate particles of high resistance to heat and acid attack

- Affinity for water: The particles have a surface chemistry that attracts water and holds onto it

- Surface area: Only bentonite and similar minerals have a higher surface area than ball clays

- Very high plasticity: They are suitable as binders, suspenders, plasticizers.

Process Properties

As a ball clay, it improves the plasticity of any body recipe to which it is added. However, it will also increase drying shrinkage, slow down drying time and increase the difficulty of drying ware without cracking.

A2 contains some soluble salts. These are hostile to the deflocculation process - so this material is not suitable in casting body recipes.

Although A2 powder looks like many other ball clays, it is not fine-ground to 42 mesh (we do not have equipment for 200 mesh). A2, as supplied by us, is not suitable in porcelains or whitewares. However, in native rustic stonewares it contributes and earthy and natural look to the fired surface.

Other applications: We can produce custom lesser mesh sizes and package in bulk bags for non-ceramic applications (please call).

Firing

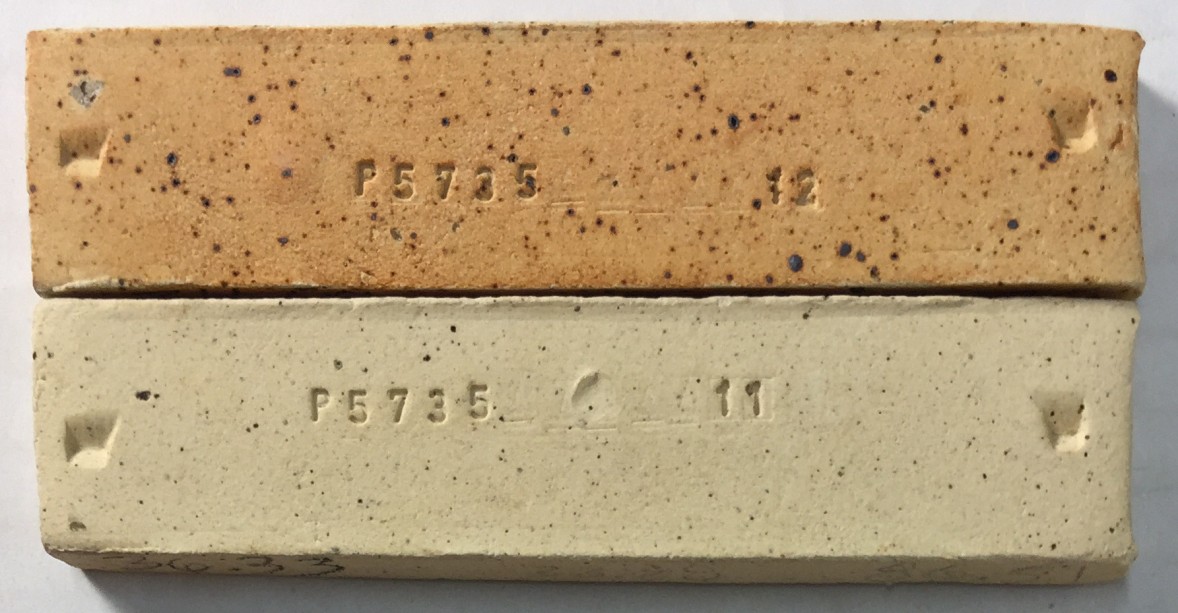

A2 has significant iron content so it does not fire white. The soluble salts in A2 will produce a flashing effect during firing in reduction, turning the cream colored surface to brownish. Since we only grind the standard material to 42 mesh, A2 will bring fired speckle to reduction bodies (these are ironstone concretion particles that fuse in reduction atmospheres).

Physical Properties

Drying Shrinkage (50:50 calcine:raw mix): 5.5-6.5% Drying Factor (50:50 calcine:raw mix): C130 Dry Density (50:50 calcine:raw mix): 1.80

Sieve Analysis (Tyler mesh):

35-48: 0.1-0.4% 48-65: 1.0-3.5 65-100: 1.5-5.5 100-150: 1.0-4.0 150-200: 3.0-7.0 200-325: 5.0-9.0

Fired Shrinkage (50:50 calcine:raw mix):

Cone 6: 4.0-5.0% Cone 8: 4.5-5.5 Cone 10: 5.5-6.5 Cone 11: 5.5-6.5

Fired Absorption: (50:50 calcine:raw mix)

Cone 6: 11.0-15.0% Cone 8: 9.0-11.0 Cone 10: 7.0-9.0 Cone 11: 6.0-8.0

Chemical Analysis

CaO 0.25 K2O 0.69 MgO 0.43 Na2O 0.04 TiO2 0.72 Al2O3 18.99 SiO2 65.12 Fe2O3 1.84 LOI 10.58%