Woodfire

Description

We no longer produce this body. However, from the following information you may be able to choose an alternative, make it yourself or use an engobe. The recipe of this body was:

- 30% Helmer kaolin

- 20% #6 Tile kaolin

- 20% Spinks Blend ball clay

- 10% silica

- 10% Nepheline Syenite

- 10% Minus 35mesh grog.

Plainsman Woodfire was a high temperature, plastic, light buff burning lightly grogged stoneware containing Helmer Kaolin. You can adjust this recipe, here are some ideas:

- Switch the #6 Tile kaolin to Helmer (giving 50% total Helmer) for even better flashing. However plasticity will be lost, you will have to add some bentonite, start with about 1%.

- For more vitreous, increase the feldspar. For less vitreous, reduce it.

- For a smoother texture, eliminate the grog. This will give better density and hardness. This will increase plasticity and drying shrinkage, so be ready to cut bentonite or use less highly plastic #6 Tile and more non-plastic Helmer.

- If you know of a ball clay that flashes well, substitute it for this one).

Most wood firing is done to achieve an effect called "flashing", generally an orange/red/brown coloration on the unglazed body surface. It is known that certain ball clays and kaolins flash better than others (specifically Helmer Kaolin, also #6 Tile). Philosophies and body preferences vary greatly in the woodfire community, please test this material in your circumstances.

Substitutes For

Since the recipe is here you could mix it yourself (if you have facilities to do that). If you are firing past cone 10 you could wedge together H550 and H441G to get about the same maturity and fired color as Woodfire. However testing will be required to see if it flashes well. If you are firing to cone 10 or lower, then any of our cone 10R bodies will work, their color at cone 10R will be a good indication of how they will appear in wood firings.

Engobes and slips are the best method to get flashing on surfaces. Their advantage is that you can employ high percentages of materials known to flash (and be able to use any stoneware body underneath them). Simply apply these to our stoneware bodies. Engobes are applied more thickly at the leather hard stage and they need to have about the same fired shrinkage as the body. Here is an flashing engobe (L3954M) we have been testing (you must test it yourself also):

Nepheline Syenite 17 Silica 18 Helmer Clay 60 Calcined Alumina 5 Bentonite 5

We found that this one does not work at the normal 1.43-1.45 specific gravity (used for glazes), it needs more water (about 140g per 100 of powder).

Process Properties

While 10% fine grog has been added, the feel of this body is quite smooth. The high kaolin content coupled with the plasticity of additional ball clay impart a throwing character similar to a Lincoln Fireclay body, very pleasant to work with. Since this body is quite plastic we recommend care in drying (even though it contains grog).

Casting: Helmer kaolin responds well to deflocculants so this body should work well (although it might cast slower than others because of the high clay content). It would be best to remove the grog from the recipe, this will lower the fired porosity somewhat. Consider using 50% Helmer (instead of 30 Helmer and 20 #6 Tile) for the best possible flashing.

Firing

Plainsman Woodfire clay is a stoneware, suitable for functional pottery. It is less vitreous than our other cone 10R buff burning stoneware bodies (e.g. H550, H450) to give margin for over-firing (since wood firings after exceed cone 10). If your wood kiln goes higher than cone 10 the typical 3% porosity will drop producing a fairly vitreous result (by cone 12 this could drop to 1% producing quite a vitreous product). Some isolated iron speckles will occur in reduction firing, these are from the grog and Helmer.

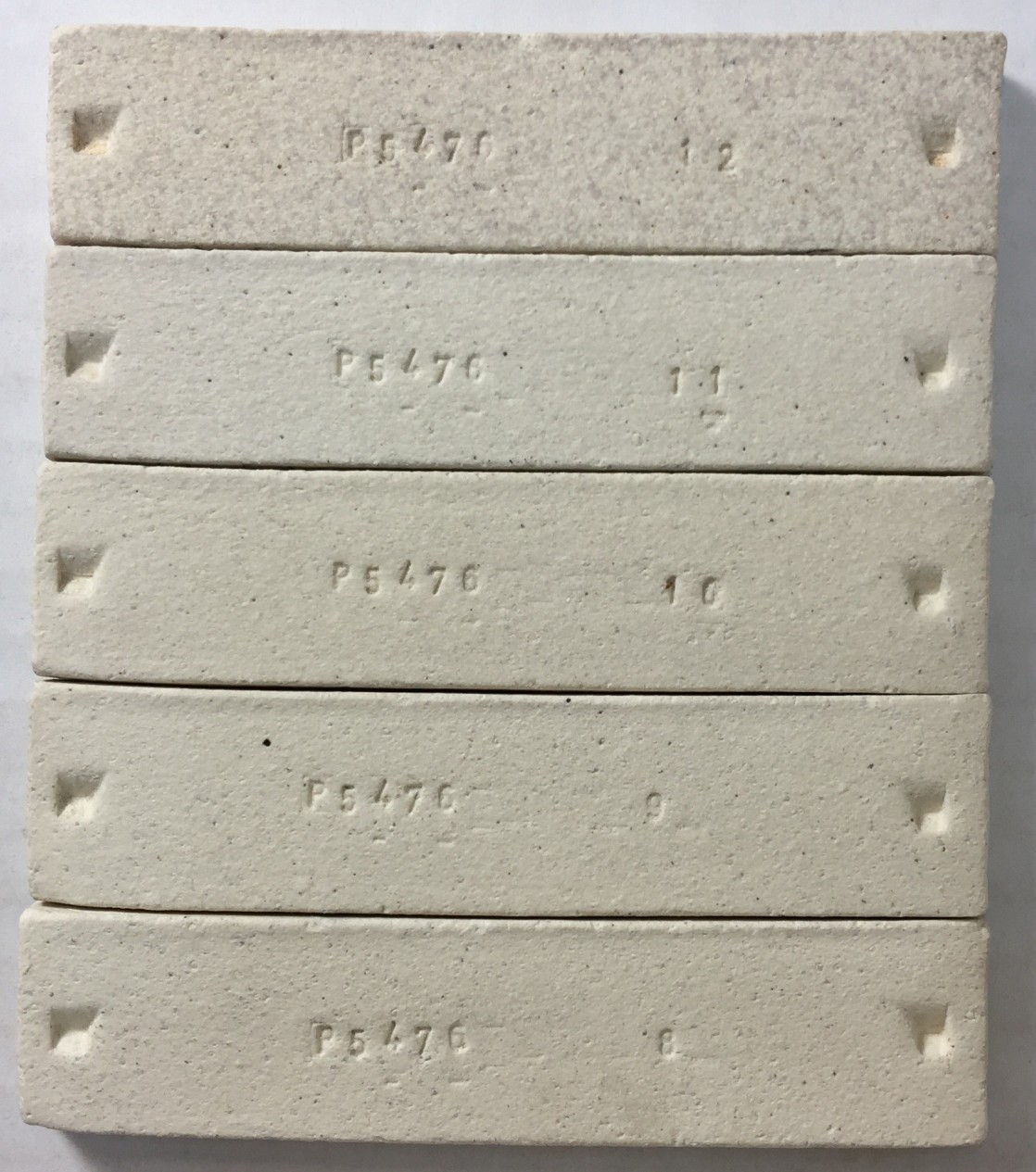

Woodfire Clay fired bars. Cone 10R (top), cone 10, 9, 8 oxidation below. These are all fired in an electric kiln, thus there is no flashing effect.

Here is an example of a flashing effect achieved in a the kiln at the Medalta Artists in Residence program.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.0-6.5%

Sieve Analysis (Tyler mesh):

+35mesh: 2.0-3.0% 35-48: 2.0-3.0 48-65: 3.0-5.0 65-100: 3.0-5.0 100-150: 2.0-4.0

Fired Shrinkage:

Cone 8: 6.5-7.5% Cone 10: 7.0-8.0 Cone 10R: 7.5-8.5

Fired Absorption:

Cone 8: 6.0-7.0% Cone 10: 3.5-4.5 Cone 10R: 2.5-3.5