3B Stoneware

Description

3B clay is a vitreous cone 5-7 moderate plasticity smooth stoneware. It's Ravenscrag quarry seam is 4-6 feet thick. This material is fine enough that a simple slaking process on the dry lumps will create a slurry of which +99% passes a 200 mesh screen!

A 10kg lump of B clay at the quarry (from the center section of the seam). It is layered, the lines run horizontally in the clay bed. It splits apart in layers, revealing carbon stringers of Cretaceous plant life.

B clay cannot be effectively deflocculated. Soluble materials within the clay impede the action of normal deflocculants resulting in gelling of the slurry.

Process Properties

B clay is incredibly smooth and fine-grained (when particulate impurities have been removed). This mug demonstrates the best it can be (it is made from a selected unprocessed lump from the center of the seam).

This material is from another lump from the same stockpile (a close-up of the thrown surface on the inside of a bowl). These are the particles that can be removed (if you have processing equipment) to produce an ultra-smooth texture.

Firing

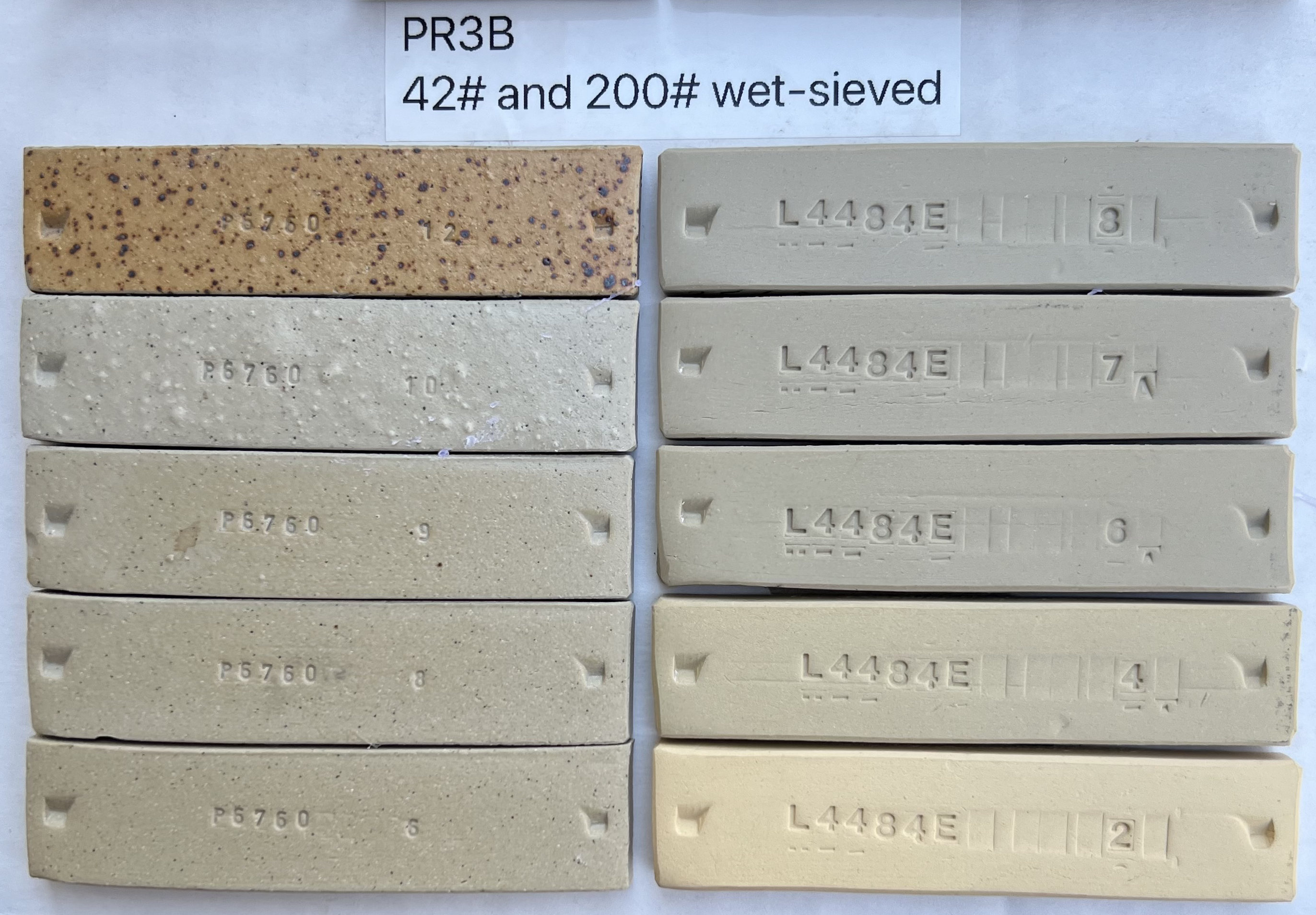

325mesh 3B and 3D fired bars. 3B ones are fired from cone 8-2 (top to bottom), the 3D ones from cone 9-3 (top to bottom). The 10% added Nepheline Syenite in the 3B reveals its iron content (firing tan to brown at cone 6). 3D, by itself, is a dense stoneware by cone 6, firing considerably whiter than 3B.

Since B clay has built-in feldspar, it is naturally vitreous at stoneware temperatures. Since feldspar additions are not needed, it possible to create bodies having better workability. It does fire with increasing iron specks as it vitries (especially in reduction), this is due to natural iron pyrite particles in the upper section of the seam).

The 3B seam, as a whole, has particulate contamination that reveals as fired speckle when the clay vitrifies. Because the impurities are relatively large particles, they can be removed by processing to make a completely smooth porcelaineous body.

Glaze Recipes

Since B clay has siqnificant natural raw quartz content it is not difficult to fit stoneware glazes, especially at higher temperatures. It will present few problems with regard to glaze pinholing if processing removes the particulate impurities.

Physical Properties

Drying Shrinkage: 5.5-6.5% Drying Factor: C120-

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0-0.1% 48-65 (300-210 microns): 0.0-0.3 65-100 (210-149 microns): 0.5-1.0 100-150 (149-106 microns): 0.5-1.5 150-200 (106-75 microns): 2.5-4.0

Fired Shrinkage (+/- 0.5):

Cone 5: 7% Cone 6: 7.5% Cone 7: 7.5%

Fired Absorption:

Cone 5: 0.5% Cone 6: 0% Cone 7: 0%

Chemical Analysis

BaO 0.4 CaO 0.2 K2O 2.2 MgO 0.5 Na2O 0.1 TiO2 0.6 Al2O3 15.6 P2O5 0.0 SiO2 72.7 Fe2O3 1.2 MnO 0.0 LOI 6.5%