Midstone

Description

A fine grained, medium plasticity, buff burning native stoneware material reaching vitrification and very high strength at cone 7. Midstone is a natural mined material from southern Saskatchewn.

Process Properties

From a working properties point-of-view, Midstone is well balanced enough to be suitable as the main constituent for middle and high temperature bodies. It contains a small amount of ball clay that we can increase or decrease to compensate for changes in plasticity. It also has a small complement of 3D silty stoneware to provide adjustability to maintain texture, particle size and drying properties.

Midstone contains soluble materials that are hostile to the deflocculation process, thus it cannot be used in casting slips.

Midstone-based bodies offer these advantages:

- It vitrifies and reaches maximum fired strength around cone 7-8. Thus is it entirely feasible to make Midstone-based stoneware bodies that contain no feldspar at all. For a cone 10 body as that is needed is some ball clay.

- It is a natural clay blend ground only to 42 mesh. No 200 mesh industrial mineral clay can match its natural feel and fired character. Notwithstanding this, Midstone is quite clean and speck free in oxidation.

- Midstone is high in free silica, so bodies employing a significant percentage require no added silica.

- Its natural iron-pyrite particles produce a light speckle in reduction. There is no better way to get a consistent reduction speckle in a cone 10R body.

Firing

Midstone fired bars (cone 8 down to 4 oxidation). The current material provides the best compromise between fired strength, color and stability in the kiln at cone 6.

Midstone burns to a light straw color at cone 5, progresses to a solid light grey-buff at cone 7-8 and grey in reduction.

Midstone contains a small amount of talc used to control its maturity. In the event that the mix becomes more refractory or more vitreous we increase or decrease the talc to compensate.

Glazing

Bodies made from Midstone are easy to fit glazes to (because it has a high natural quartz content). Ones that craze on porcelain will likely fit Midstone.

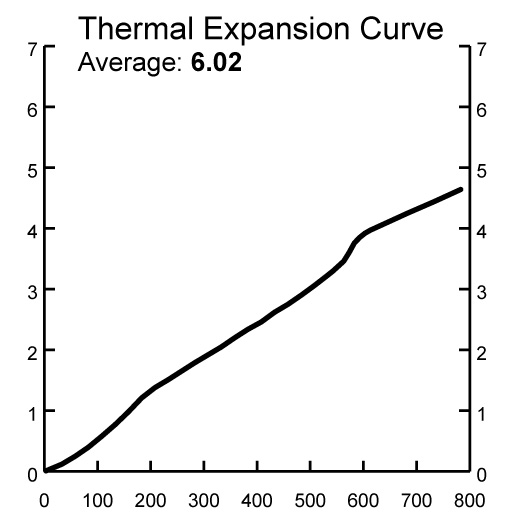

Thermal Expansion

This chart was derived from a specimen fired once to cone 6 in the Plainsman lab and tested in an Orton dilatometer. It is a general guide only. If you fire to a different temperature, employ different heatup or cooldown rates, or glaze-fire more than once the thermal expansion in your ware may be different than this chart indicates.

Physical Properties

Drying Shrinkage: 5.8-6.8% Drying Factor: C120

Sieve Analysis (Tyler mesh):

48-65: 0.25-1.0% 65-100: 2.0-4.0 100-150: 2.0-3.5 150-200: 5.0-8.0

Fired Shrinkage:

Cone 4: 3.5-4.5% Cone 6: 5.0-6.0 Cone 8: 5.5-6.5

Fired Absorption:

Cone 4: 4.0-5.0 Cone 6: 2.0-3.0 Cone 8: 0.5-1.5

Chemical Analysis

BaO 0.4 CaO 0.2 K2O 2.0 MgO 0.8 Na2O 0.1 TiO2 0.6 Al2O3 18.2 P2O5 0.0 SiO2 68.2 Fe2O3 1.4 MnO 0.0 LOI 8.0%