Normal Hours of Operation Mon-Fri: 8am-4.00pm

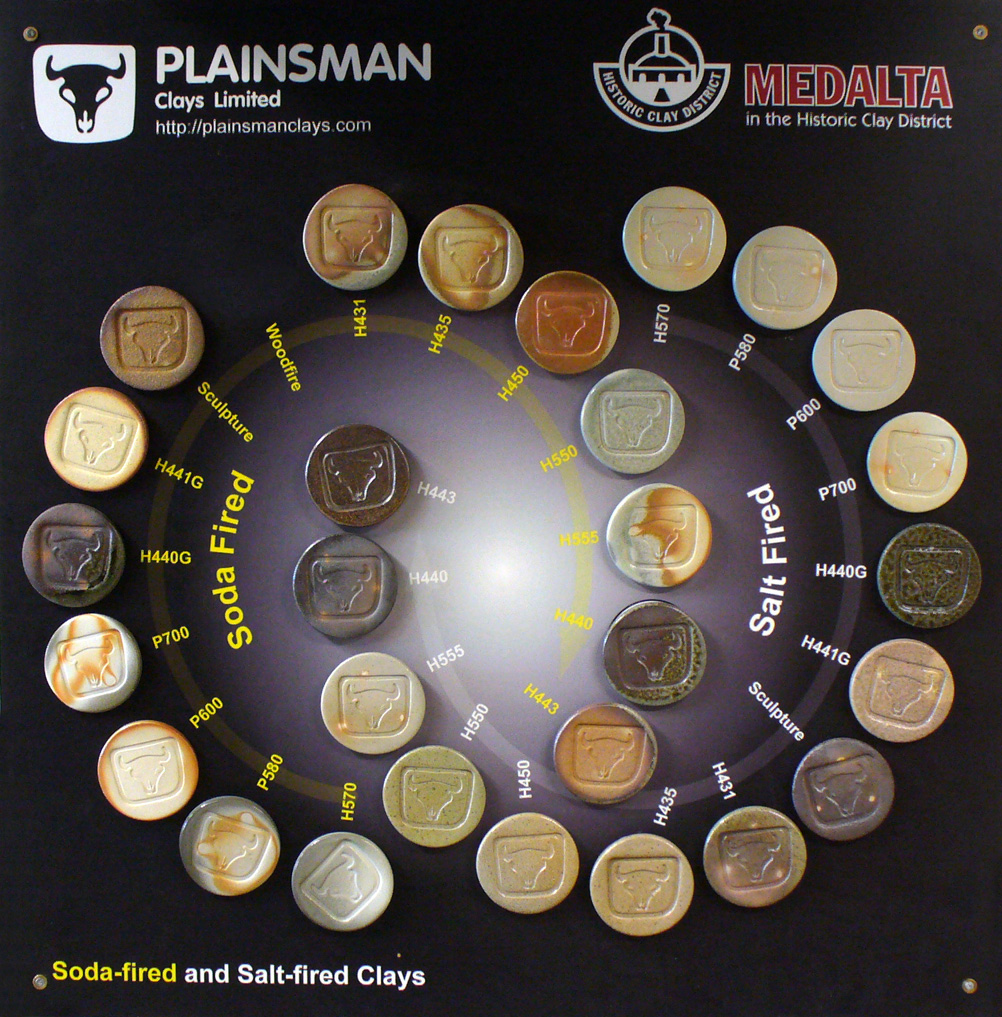

Information About Plainsman Products Services & Information ClaysLow Temperature ClaysMedium Temperature Clays High Temperature Clays Porcelains Other Clays Native Clays Casting Slips MaterialsDry MaterialsStains Encapsulated Stains Liquids GlazesSpectrum Opaque Gloss Low Fire GlazesSpectrum Metallic Glazes Medium Fire Glazes Plainsman Dry Glazes Potter's Choice Cone 5/6 Glazes Celadon Cone 5/6 Glazes Amaco Satin Matte Glazes Liquid Brights UnderglazesAmaco Velvet UnderglazesEnamellingEquipmentKilnsElectric Pottery KilnsElectric Glass Kilns Kiln Furniture Cones Elements Kiln Parts, Accessories Exhaust Systems Refractories Potter's Wheels Slab Rollers Hand Extruders Pugmills Scales Banding Wheels Air Brushes ToolsBrushesThrowing Tools Trimming, Turning, Cutting Tools Wood/Bamboo Tools Rollers/Stamps Decorating Tools Glazing Tools Ribs & Scrapers Ribbon/Wire Tools Rasps Knives, Needle Tools, Cutters Tool Kits Unclassified AccessoriesMiscellaneous AccesoriesCorks/Stoppers Cork Pads Oil Lamp Accessories Dispenser Pumps Teapot Handles Bisque Tiles | Atmospheric FiringAtmospheric firings, as processes, are much less predictable than typical electric or gas firing. Potters develop their own methods. Part of adopting the process is being willing to do plenty of testing to find something that works for you. The color and maturity of all our high-fire clay bodies are well documented, use this data and common sense to decide which are best to use. The salt and soda firing processes depend on the mechanism whereby sodium vapour in the atmosphere of a kiln combines with SiO2 and Al2O3 on the surface of the clay to form a glaze. Our native high-temperature, buff-burning bodies (e.g. H550, H450) are high in quartz, thus they are inherently suitable for this. Our high-temperature porcelains also contain around 25% quartz, potters routinely use them (e.g. Jim Etzkorn has used P600 with very good success). Firing Temperature: H550 is designed to be as vitreous as its particle-size will reliably permit. Firing higher than cone 10R could produce bloating. H450 has more margin for over-firing. The brown-burning bodies like H443 and H440 have a fairly high porosity (needed to develop the warm coloration in reduction), these can thus endure higher temperatures. H441G is our most refractory body and it develops flashing because of iron-stained soluble salts, this would likely be interesting in atmospheric firings. Except for H570, our porcelains burn at zero-porosity, there is thus a bloating danger if these are fired too high in untested atmospheres. Make your own body: Plainsman Fireclay can be blended with about 25% Nepheline Syenite to produce a vitreous and plastic body at cone 10. After testing adjust the percentage of Nepheline to produce the maturity needed. The firelcay has more soluble salts than our other materials, these come to the surface during drying and produce flashing that will be enhanced by atmospheric firings. Add 1-3% bentonite if more plasticity is needed.

|

Plainsman Clays, 671 Industrial Ave, Medicine Hat, Alberta T1A 3L5

Phone: 403-527-8535

FAX: 403-527-7508