Snow

Description

Low temperature, smooth, plastic, white-burning, refined dolomite earthenware for modelling or casting. Snow is available in a pugged plastic version and as a casting slip.

We have tested Spectrum 700 series glazes the most. On the left is Spectrum 748 fire engine red cone 04 glaze (three coats) on a thrown piece. On the right is Amaco V-388 underglaze covered with Spectrum 700 transparent (3 coats each) on a slip cast piece. Both Snow mugs were glaze fired to cone 05 and bisque fired to cone 04.

News

- Jan 2022: The entire industry is phasing out of the use of talc, it happened suddenly. This new talc-free body replaces the former L213. It is better than L213 in some ways and has some disadvantages.

- May 2022: Do not expect everything to be exactly the same as with L213. The most important things are: It is highly plastic, dries well, fires very white, fits commercial glazes at cone 06-04.

- June 2022: Please read the section below about hydration: In damp climates bisque ware can crack if left out in the air for extended periods.

- Jan 2023: Other manufacturers are again making talc bodies, but using dirtier talcs - we are sticking with this recipe. Customers who have adapted and reported good results.

Process Properties

Snow is highly plastic yet drying performance is excellent (other plastic bodies we made require much more care). It is more fragile in the dry state than other clays. Snow is good as-is for hand-building and sculpture but can tolerate sand or grog additions (e.g. 10%) for making large sculptural pieces.

You can make forms that combine plastic elements made from Snow and mold-made elements made from Snow Casting. Use care to keep water content even during drying (since cast sections will likely be thinner than modeled or thrown ones).

Firing

Snow burns very white from cone 06 to cone 02. We do not recommend any particular firing schedule, but faster firing can help if the glaze is soaking into the body too much. Or, try to discover the temperature at which the glaze just begins to absorp and fire just below that (likely around cone 06). Snow pieces will endure (and glaze surfaces even improve) through many re-firings. This, combined with the low temperature of the firings, makes complex decorating techniques that require multiple firing practical.

Snow has high porosity, as high as 25%. This has obvious disadvantages but also advantages. Snow clay has zero% fired shrinkage across the entire range to cone 4 (after that it rapidly vitrifies and shrinks)! That means it is possible to make tiles that do not change in size or warp during firing (even if fired on stilts)! The porosity enables glazes to form a good interface and glazed ware can be surprisingly resistant to failure on impact. Here is a video of dropping a mug onto cement: Click here!

Dolomite hydration: Bisque firing dehydrates the limestone in Dolomite. While the dolomite particles are somewhat neutralized by being isolated and having reacted with the clay and feldspar particles, they still seek an opportunity to rehydrate, this can cause splitting. If you live in a damp climate, leaving bisque ware sitting around for weeks could cause failure. Do not wash bisque and leave it sitting. Glaze ware soon after bisquing and dry it as quickly as possible. Glaze all the surfaces of ware possible. If bottoms cannot be glazed then render them impervious to water penetration by using a silicone sealer.

Snow clay, although high in Dolomite has proven to be very resilient, but not just in physical strength. This cone 04 glazed tile has not spalled despite cycling it three times through an hours-long water immersion and week-long freezer stay. The cone 04 bisqued mug has cracked after four years storage on a shelf in our lab (but it has 60% dolomite vs. Snow's 40%).

Plainsman Snow has high porosity, but this has an advantage: It soaks up silicone sealer very well. The slip-cast piece on the left was sealed (you can see the surface sheen) and it is impermeable to water penetration (the glaze is not crazed so water cannot penetrate there either). The piece on the right soaks up water readily (on the lower unglazed portion). All pieces made using this body should either have all surfaces glazed or sealed.

Glazing

We cannot guarantee that commercial brushing glazes will not craze or shiver, please test. Regarding toxicity: Do not assume food surface safety of brightly colored glazes in your kiln without a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

These are slip-cast pieces of Plainsman Snow. We are getting best results with Spectrum 700 series glazes. Shown here are Spectrum 753 Bright Yellow, 746 Bright Purple, 706 Royal Blue, 743 Bright Red, Inside: #700. Firing schedule was BTSG05, bisque was BTFB04.

How many mugs can this jar of Spectrum 700 cover? About 7. This is Snow clay and 4 coats are needed.

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

This body fires very white yet transparent from some glaze manufacturers can produce a yellowish tone (the dolomite is reacting with glazes of certain chemistries). We recommend Spectrum 700 as the clear glaze of choice (other transparent we have tested have issues). Our G3879 dipping glaze recipe also produces a high-quality crystal clear.

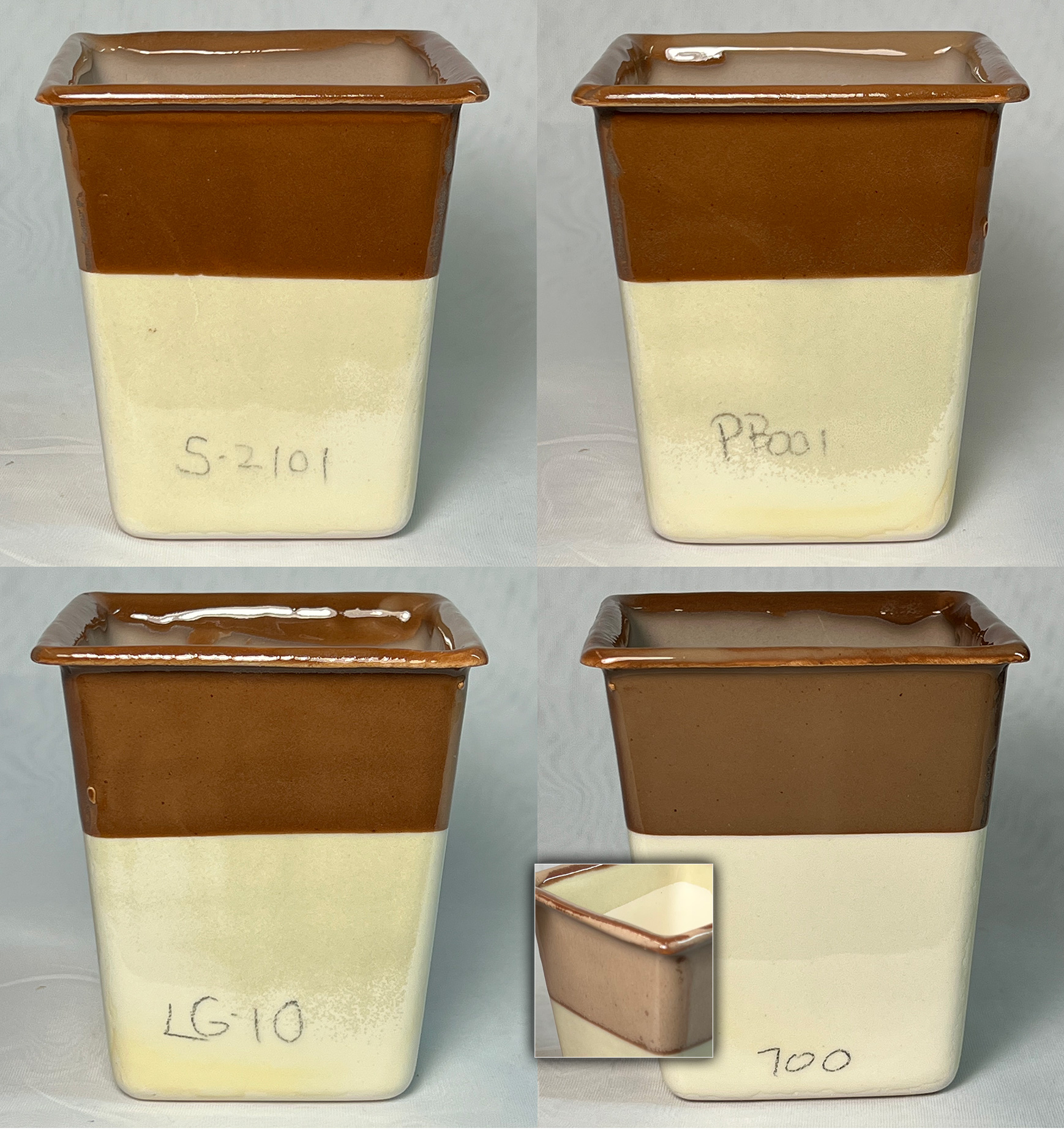

These are Plainsman Snow cast pieces with L3685Z7 stained engobe on the upper sections. They have been clear glazed with Mayco S-2101, Duncan PB001, Amaco LG-10 and Spectrum 700 transparent glazes. The left half of each has an extra glaze layer, that has not made much difference in any of them. The S-2101 transmits the brown color best, the LG-10 and PB001 a little less. The 700 is decidedly lighter, it is altering the brown color (likely MgO in the glaze is reacting with the stain). However, over the white body, the 700 is by far the best, being crystal clear and glassy smooth. The lower halves of these also demonstrate something equally interesting: The ones that don't alter the brown do react with the MgO in the white body, yellowing it and turning opaque in areas. The lesson is to try various brands of clear glazes over underglaze decoration and colored engobes, especially with dolomite-based low fire bodies. It might even be advantageous to use one brand on the insides of pieces and another on the engobe or slip-decorated exteriors.

Since Snow is more porous it can also absorb a glaze melt during firing. Consider four coats if this is an issue. Or finish colored glossy glazes with a coat of transparent.

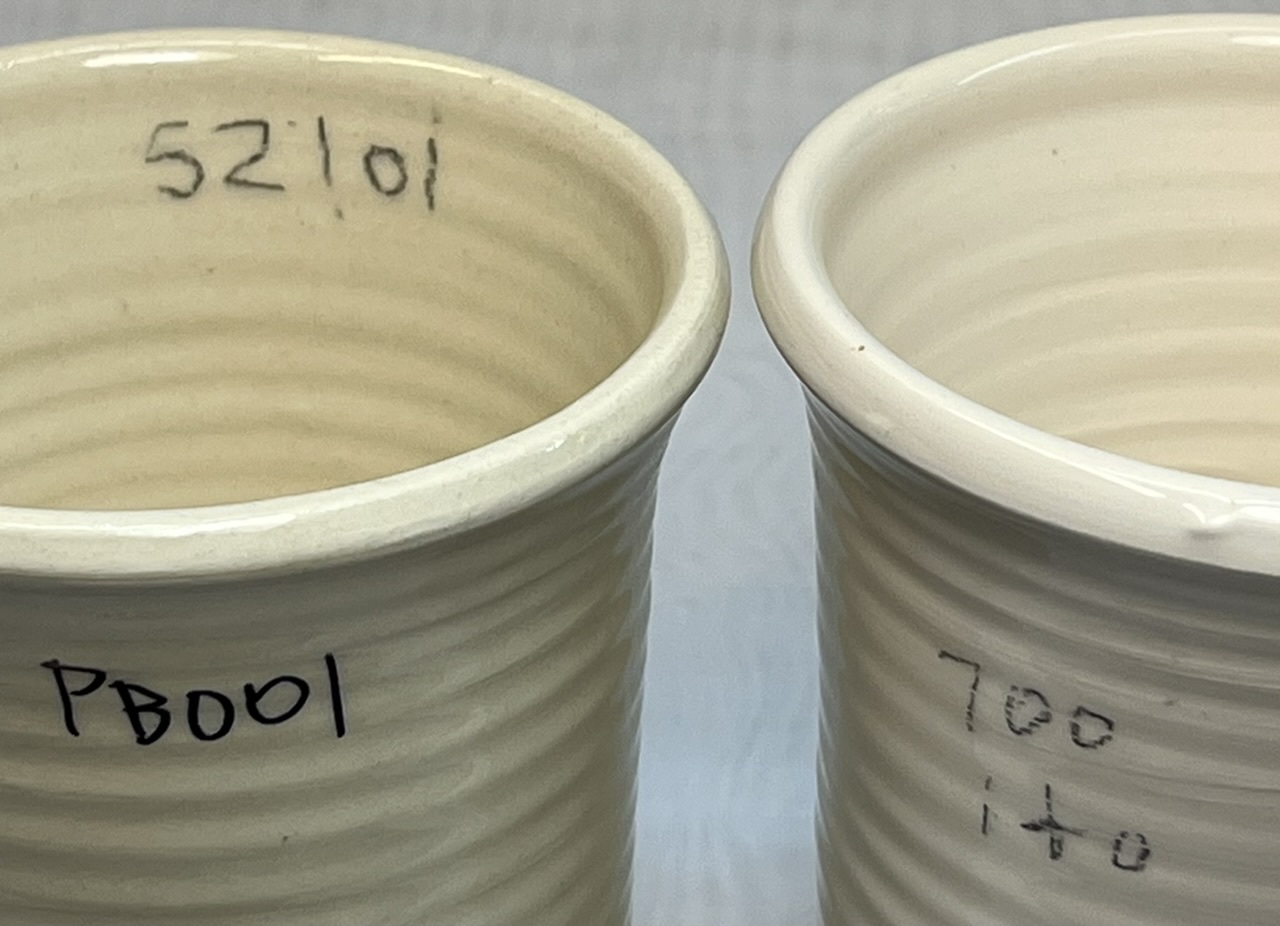

Snow clay with Mayco S2101, Duncan PB001 (left) and Spectrum 700 (right) Fired cone 05. No crazing after weeks on any of them. The 700 glaze fires much whiter than the Duncan or Mayco, the others appear to be reacting with the dolomite in Snow (they may contain zinc).

Karel Peeters applies a thin layer of glaze on the bottoms of Snow mugs, thus completely sealing the body to access by water or air.

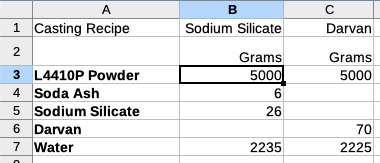

Casting Recipe

No recipe for mixing casting slip can be precise or unchanging, deflocculation depends on a delicate balance of electrolytes - small changes in water quality, materials solubility, temperature, age of deflocculant, mixing, etc can have a big effect on slip rheology. That means you need to be ready to adjust (usually in the percentage of Darvan or sodium silicate). It is thus important to be able to measure specific gravity efficiently and have a good propeller mixer. Snow is more easily over-deflocculated than L213 was (you can recognize over-deflocculation when objects cast much thinner, the leather hard surface is rough, mold release is more difficult and the Ford cup is less than 20 seconds.

In our lab we use the following recipe (Snow is referred to as L4410P, the lab test number). For sodium silicate/soda ash, consider holding back 2g/.5g (for Darvan 4g). Scale this up to the batch size that needed:

Snow requires more than double the amount of Darvan that L213 did. On initial mixing the slurry may appear too runny and thin (e.g. Ford Cup of 15-20 seconds). Take advantage of this and mix it really well because it thickens overnight. If you over deflocculate (it is too thin), add 1 gram of water-dissolved Epsom salts for each 3000g of powder in the mix (within a minute of propeller mixing the slip should thicken, repeat if needed). For maximum casting rate use the slip thicker (if a less even drain can be tolerated). The better the slip the more smooth the leather hard poured surface will feel.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 5.0-6.0% Dry Strength: n/a Water Content: 19.5-20.5% Drying Factor: A000 LOI: 24% Dry Density: n/a

Sieve Analysis (Tyler mesh):

65-100: 0.1-0.2% 100-150: 0.1-0.4 150-200: 1.0-2.0

Fired Shrinkage:

Cone 06: -0.2% Cone 02: -0.6 Cone 2: -1.0 Cone 4: -0.5 Cone 6: 7.0

Fired Absorption:

Cone 06: 28% Cone 02: 28 Cone 2: 28 Cone 4: 27 Cone 6: 12

Gallery

AMACO Velvet underglazes were applied to the slip-cast Snow pieces at the leather hard stage. The back piece was fired at cone 05. The front one went to cone 6, while this clay sags and warps at the high temperature it does not bloat and has not become brittle. The high porosity holds to cone 4, then suddenly drops through cone 5.

Plainsman Snow clay makes this QRCode mosaic possible. The tile onto which each porcelain pixel is glaze-glued is made of Snow. During firing to cone 04, it has zero shrinkage. And it does not curl up at the edges. All other plastic clays do both of those! Snow continues this performance for ten more cones (to 4). We silicone-sealed this work front and back, now it is ready for outdoor installation.

Snow clay with G3879C brushing clear glaze and Amaco V-303 terra cotta underglaze on the bottom section. This mug looks like a terra cotta but has a much more flawless glaze surface than is normal on a terra cotta.