L213

No longer available as of Feb 2022. Please use Snow instead. We can give you the recipe of this if you would like to make your own.

Description

Low temperature, smooth, plastic, white-burning, refined high-talc earthenware for modelling or casting. L213 is available in a pugged plastic version and as a casting slip. Both are a 50:50 mix of Texas Talc and KT#1-4 Ball Clay. Each has a 2.5% addition of calcium carbonate. This recipe is a standard that has been used in hobby ceramics across North America for many decades. The casting version of L213 adds 0.5% bentonite and the throwing one 3.5% bentonite. L213 is the best choice for people who intend to use commercial premixed glazes from companies like Duncan, Mayco, Gare, Spectrum, etc. and who need a white burning material.

News

Jan 2022: The entire industry is phasing out of the use of talc, it is happening suddenly, so this body is discontinued. The new talc-free "Snow" is now available in both plastic and casting version.

Process Properties

Having 50% ball clay (plus bentonite) this body is obviously plastic. However, to fully benefit from the plasticity be sure the clay is not too soft, thoroughly wedge before throwing and center pieces well before pulling them up. If the material is too soft consider stiffening it on a plaster batt before use.

You can make forms that combine plastic elements made from L213 and mold-made elements made from L213C. Consider using the deflocculated slurry to join sections (its low water content produces less shrinkage). Use care to keep water content even during drying (since cast sections will likely be thinner and have a more even cross-section than modeled or thrown ones).

Firing

L213 burns very white from cone 06 to cone 2. This is due to the lack of a glassy phase (that darkens iron) and the use of special whiter-burning ball clay and talc. As a result, a transparent glaze (for cone 06-04) produces white ware and colored glazes fire to brighter shades. Above cone 2 the fired body color shifts to grey-buff and it becomes increasingly more brittle. Please experiment in your circumstances to determine how high you can practically fire it.

The large amount of talc in L213 increases the thermal expansion of ware fired at cone 04-06. Care is required if ware will be used for functional purposes requiring thermal shock resistance.

The new Snow body has a distinct advantage over the old L213: It has zero% fired shrinkage over a wide temperature range (as high as cone 4). That means it is possible to make tiles that do not change in size or warp during firing. It also has a disadvantage: High porosity, as high as 25%. However, it appears that does not affect body strength (likely the pores are very tiny, a product of the dehydration of the dolomite). The porosity does not appear to change glazing characteristics. It actually has an advantage: The fired matrix absorbs sealants readily, making it a candidate for outdoor pieces.

Glazing

We cannot guarantee that commercial brushing glazes will not craze or shiver, please test. Regarding toxicity: Do not assume food surface safety of brightly colored glazes in your kiln without a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

For slip decoration and engobes be careful to match the fired shrinkage of the slip with the body. Where we do not recommend a specific engobe recipe, consider one based on the body itself. Add 2% VeeGum or Bentonite (the extra stickiness helps it adhere well to leather hard ware). Be careful about adding fluxes (e.g. frit), this increases fired shrinkage creating a mismatch with body that can cause flaking (and can compromise engobe opacity).

Casting Recipe

It is important to understand the principles of deflocculation, be able to measure specific gravity efficiently and have a good propeller mixer to make good casting slip.

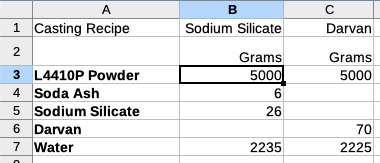

In our lab we use the following recipe (scale this up to the batch size that you need):

L213C dry 1500 g Water 700 g Darvan #7 8-10 g

Start with the minimum amount of Darvan and mix well.

This should yield a conservative specific gravity of 1.74. We do not suggest adding any more water if it is not fluid enough. Instead add more Darvan to the maximum recommended.

Recipe for L4410P (Snow), the new L213 starting in 2022

If you received the new recipe the bags will be clearly marked (otherwise it is the old talc-based one). This dolomite-based body behaves differently. It requires more than double the amount of Darvan, but it produces a higher specific gravity: 1.77. On initial mixing the slurry will appear too runny and thin (Ford Cup measure of 15-20 seconds). It is important to propeller mix it really well while it is runny because it thickens overnight - so with insufficient deflocculant or mixing it will be too viscous to mix the next day. For sodium silicate/soda ash, consider holding back 2g/.5g (for Darvan 4g). If 15 seconds on the Ford cup is achieved then don't add it.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.0-7.0% Dry Strength: n/a Water Content: 21-22% Drying Factor: A000 LOI: 11-12% Dry Density: n/a

Sieve Analysis (Tyler mesh):

65-100: 0.1-0.2% 100-150: 0.1-0.4 150-200: 1.0-2.0

Fired Shrinkage:

Cone 06: 1-2% Cone 04: 2-3% Cone 02: 2.5-3.5 Cone 2: 2.5-3.5

Fired Absorption:

Cone 06: 13-15% Cone 04: 11-13 Cone 02: 9-11 Cone 2: 8-10 Cone 4: 9-11 Cone 6: 10-13

Gallery

Buffstone, L212 and L213. Each has its own clear glaze. G2931L, G2931K and G2931H.

L is low expansion (for zero-talc porous bodies like Buffstone). K is intermediate (for moderate-talc bodies like L215, Zero3 stoneware and porcelain). H is high-expansion (for higher-talc bodies like L212, L213).

Safety Data Sheet

Click here for web view.We Are Rationalizing Our Product Line

Plainsman manufactures bodies by grinding and pugging clays that we mine (native bodies) and by batch mixing bagged minerals and materials that we import (refined bodies). We stock about 10,000 boxes of 50+ clays (some in multiple stiffnesses) and need to reduce the warehousing and production burden of small-run bodies and remove obsolete and legacy products. For bodies being discontinued: We have migration paths and can assist with issues. Some changes involve increased cost. In certain cases you might consider having us custom-mix a body so you can continue to get it, but please work with us on trying to adapt to alternatives first.