L212

Description

Low temperature, smooth, medium plastic, light cream to grey buff burning, refined talc earthenware. L212 is a mix of our native stoneware clay, A3, with talc, ball clay and bentonite. It is typically used with commercial bottled glazes (i.e. Duncan, Mayco, Spectrum). It is a popular body for use in schools.

Process Properties

To retain plasticity (to tolerate the talc addition) we add about 10% of a ball clay bentonite mix. These additions give the body a very pleasant, smooth feel for throwing and modelling forms of all shapes and sizes.

L212 dries fairly quickly with minimal cracking. However, it is fine-grained grained so good joining practice is still important.

Firing

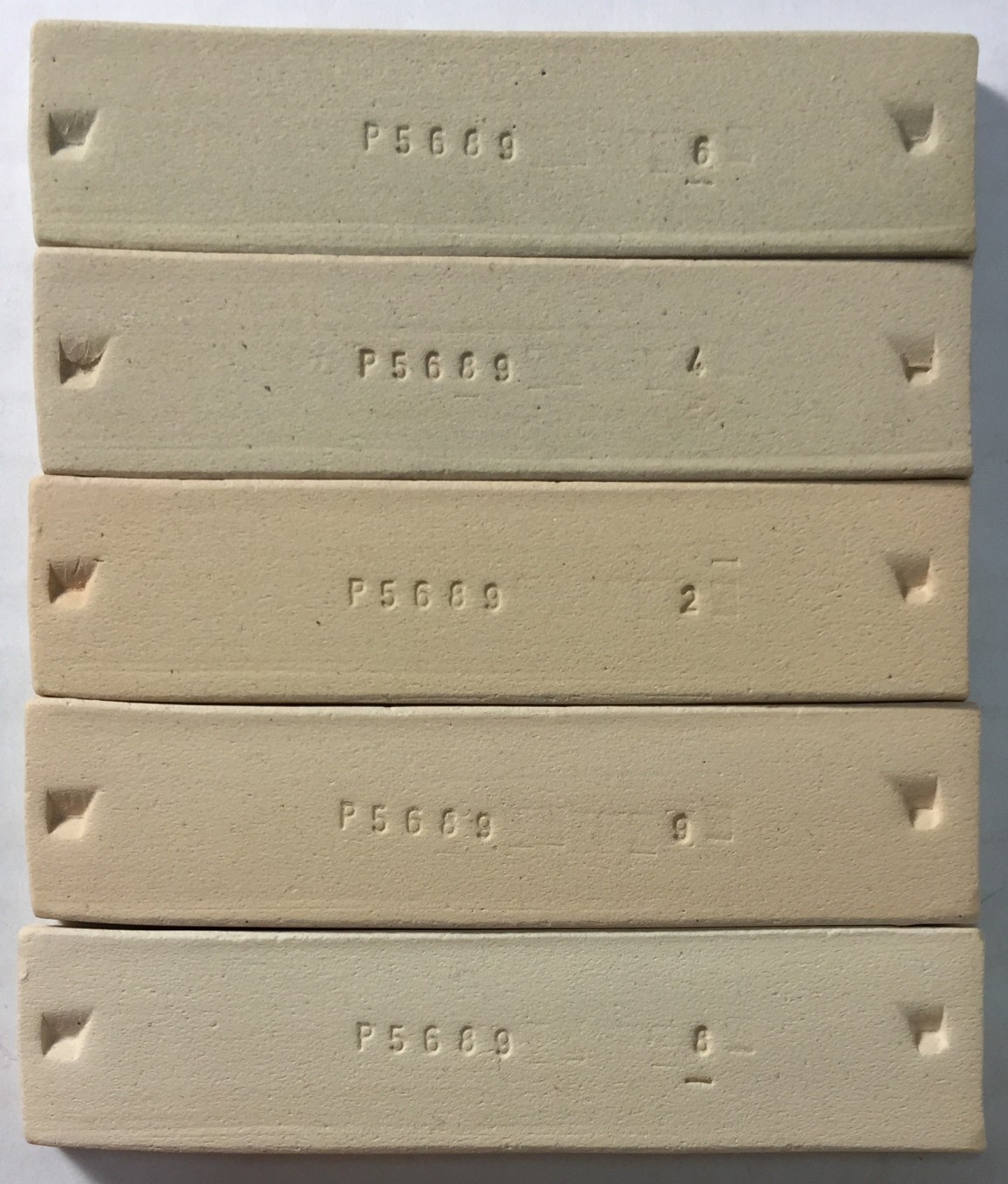

L212 is almost always used at cone 06-04 with commercial bottled glazes. The body color darkens to a yellow buff by cone 2, then to a grey buff by cone 4 and above. If glazes can tolerate it, denser stronger ware can be made at cone 03 or even 02 (while the ware is stronger, like any earthenware body, it does not vitrify at low temperatures).

The added talc increases thermal expansion. That means ware will not be as resistant to thermal shock failure (cracking if suddenly heated).

L212 is not made from white burning ball clay and talc (as are typical ceramic casting slips), thus it burns to a darker color.

Since L212 contains bentonite, be careful not to fire too fast during early stages. Likewise, ball clay is very fine and does not vent water vapour as quickly during the water smoking period of firing. It is good practice to candle the kiln overnight to give the ware a chance to dry thoroughly before starting the firing the next morning.

To get the best defect-free surface please consider using the drop-and-hold slow-cool 04DSDH firing schedule.

Glazing

L212 underglaze decorated mug fired at cone 03. Outside glaze is G2931H clear. The liner glaze is Crysanthos SG001 white.

L212 contains 30% talc. This significantly increases the thermal expansion of the ware (when heated) and thermal contraction during cooling. That contraction squeezes the glaze onto the ware and helps prevent crazing. The percentage is tuned so that most glazes fit.

We cannot guarantee that commercial brushing glazes will not craze or shiver, please test. Regarding toxicity: Do not assume food surface safety of brightly colored glazes in your kiln without a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

For slip decoration and engobes be careful to match the fired shrinkage of the slip with the body. Where we do not recommend a specific engobe recipe, consider one based on the body itself. Add 2% VeeGum or Bentonite (the extra stickiness helps it adhere well to leather hard ware). Be careful about adding fluxes (e.g. frit), this increases fired shrinkage creating a mismatch with body that can cause flaking (and can compromise engobe opacity).

Buffstone, L212 and L213. Each has its own clear glaze. G2931L, G2931K and G2931H.

L is low expansion (for zero-talc porous bodies like Buffstone). K is intermediate (for moderate-talc bodies like L215, Zero3 stoneware and porcelain). H is high-expansion (for higher-talc bodies like L212, L213).

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.0-7.0% Dry Strength: n/a Water Content: 21.5-23.0% Drying Factor: C120 Dry Density: 1.96

Sieve Analysis (Tyler mesh):

+65: 0.1-0.5% 65-100: 0.5-1.5 100-150: 1.0-2.0 150-200: 1.0-2.0 200-325: 6.0-10.0

Fired Shrinkage:

Cone 04: 1.5-2.5% Cone 02: 3.0-4.0 Cone 2: 4.0-5.0

Fired Absorption:

Cone 04: 11.0-14.0% Cone 02: 9.0-12.0 Cone 2: 5.0-7.0