P580

Due to very limited sales of P580 we have chosen to discontinue production this clay body. Please consider using H570, P700.

Description

High temperature, smooth, medium plastic, grey-white firing, refined body for reduction and oxidation porcelainous stoneware.

P580 is a variation on the classic '25 Porcelain' mix (25% ball clay, kaolin, feldspar, silica). It uses a blend of 36% ball clays and 12% kaolin to produce a body of greater plasticity. It also has additional bentonite to increase plasticity further. P580 maintains excellent drying properties and is well suited to machine production since it has high leather hard and dry strength compared to porcelains.

While P580 is not quite as white as fine porcelains, it still maintains near zero absorption for functional ware. Thus it is a material-of-choice compared to porcelains if the fired color is acceptable for your application. However, if you can tolerate a slightly darker fired color, we recommend H555.

Process Properties

P580 is a smooth and slick fine grained body that throws and dries quite well compared to all-kaolin porcelains. Its ball clay complement gives it a robust nature that makes it a good choice for machine forming and even hand building. It generates very little slip during throwing and does not work as well when too soft as do more plastic bodies.

Drying: Porcelains do not dry as well as stonewares or bodies with particulates. You will get the best results if the clay is not too soft, ware is not too thick, contours are smooth, wall thicknesses are even, joins are few and done with thick slip, the degree-of-wetness in all parts of a piece is kept equal throughout all stages of drying. Large pieces are best made on plaster bats so the bottom can stiffen with the walls. The worst drying performance will occur with thick ware made from very soft clay, the use of non-absorbent bats, where vessel walls are thick at the bottom and thin at the lips or edges, walls are of uneven thickness with lots of joins or abrupt angles (giving cracks a place to start) and where drying is uneven (e.g. lips and edges are permitted to stiffen early on while lower sections remain soft). Large, flat plates are the most difficult shapes to dry, it may be necessary to stretch the time out to a month or more to achieve the even drying needed for success.

Firing

P580 fires darker than P600 or P570. However, its color is stable across the cone 8-10 range in oxidation and its reduction color is quite consistent from firing to firing.

P580 is quite mature (but not vitrified to zero porosity), it contains 24% each of feldspar and silica. It thus produces a very strong product. Thus you must take precautions to make shapes that have inherent strength to resist warping (i.e. avoid goblets with flared bases, flared or overhung bowls). Kiln shelves must also be be flat. You may need to use a little kiln wash to separate lids and vessels.

Glazing

P580 has a fairly high flint content and is thus easier to fit glazes to than P600.

P580's high strength can be severely compromised if a glaze is under excessive compression or tension. We recommend that you stress-test a piece of ware using a boiling water:ice water test. Ware should be able to survive several two-minute cycles before trouble appears. If you need assistance to adjust the thermal expansion of your glazes, please contact Plainsman.

If you wish to use slip on your ware, make it from a base of P580 itself if possible.

Glaze Recipes

Commercial brush-on glazes: They may or may not fit our clays (check for glaze fit using a BWIW test or similar). For brightly colored glazes (especially with layering) do a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Mixing your own glazes is practical (with our clear guidelines even beginners can make dipping glazes that go on silky smooth and evenly and dry in seconds). If you already do this using recipes from the web, be careful. High-feldspar glazes (having more than about 35%) often craze. Some recipes rely on high melt fluidity to encourage crystallization and variegation (often because of inadequate SiO2 and Al2O3 or containing Gerstley Borate or Frit), view these with suspicion for leaching and cutlery marking; test them well (also test the additionless versions). Be suspicious of any glaze not having good documentation.

Consider using our G1947U glossy or G2571A matte base recipes, just add colorants, opacifiers, variegators (you will find links to much more information and pictures about these). If you have a recipe that is troublesome, consider transplanting its opacifiers, colorants and variegators to these bases instead. http://ravenscrag.com and http://albertaslip.com also have many recipes that work well on porcelains.

Crazing: Functional ware must remain craze-free (crazing is unsanitary and drastically reduces ware strength). Even though ware may not be crazed out-of-the kiln it may do so with time. Do cycles of a boiling water:ice water immersions (BWIW test) on a piece to test glaze fit (by stressing it to bring out any crazing or shivering tendencies).

Thixotropy: If you want the best application properties for one-coat dipping, consider creating a thixotropic slurry. Thixotropic glazes are creamy because they have been thinned and then gelled by the addition of a flocculant.

For slip decoration and engobes be careful to match the fired shrinkage of the slip with the body. Where we do not recommend a specific engobe recipe, consider one based on the body itself. Add 2% VeeGum or Bentonite (the extra stickiness helps it adhere well to leather hard ware). Be careful about adding fluxes (e.g. frit), this increases fired shrinkage creating a mismatch with body that can cause flaking (and can compromise engobe opacity).

If you want to develop and mix your own glazes and engobes consider getting an account at insight-live.com. You can organize a methodical development program and adopt better methods of testing (e.g. melt fluidity, thermal stress, slip-fit tests).

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 5.0-6.0% Dry Strength: n/a Water Content: 21.0-22.0% Drying Factor: C110+ Dry Density: n/a

Sieve Analysis (Tyler mesh):

+100: 0.0-0.2% 100-150: 0.0-0.5 150-200: 0.2-1.0 200-325: 2.0-4.0

Fired Shrinkage:

Cone 8: 6.0-7.0% Cone 10: 6.5-7.5 Cone 10R: 7.0-8.0

Fired Absorption:

Cone 8: 1.0-2.0% Cone 10: 0.3-0.8 Cone 10R: 0.0-0.5

Chemical Analysis

CaO 0.2 K2O 2.9 KNaO 0.0 Li2O 0.4 MgO 0.1 Na2O 0.8 TiO2 0.6 Al2O3 18.9 P2O5 0.0 SiO2 70.2 Fe2O3 0.6 FeO 0.0 MnO 0.0 LOI 5.3%

Compared to Others

The decline of the ceramic industry in North America has impacted the price, availability and quality-for-ceramics of raw materials from which porcelains are made (especially ball clays and kaolins, which have seen increases in soluble salts, foreign particles and iron specks). In addition, we do not have filter-pressing, pre-mixing and stainless-steel pugging equipment (these would drastically increase prices). While you cannot make Wedgewood-quality ware it will be far whiter and cleaner than our stonewares. Notwithstanding that, be aware that transparent glazes carry a chance of isolated specks using our standard porcelains, it is better to use white and colored glazes on these. If you absolutely need a clean, white, translucent porcelain consider using our premium products, Polar Ice and P700 (they cost more but you get much more). We are also developing engobes for low, middle and high temperature ranges, using these you can apply a porcelain-like surface of almost any color at leather hard stage and completely hide the underlying stoneware. These engobes are so opaque that a white one can completely mask a black body underneath using only one coat. So, if you can master their use (there is lots of documentation here) many new design opportunities will offer themselves.

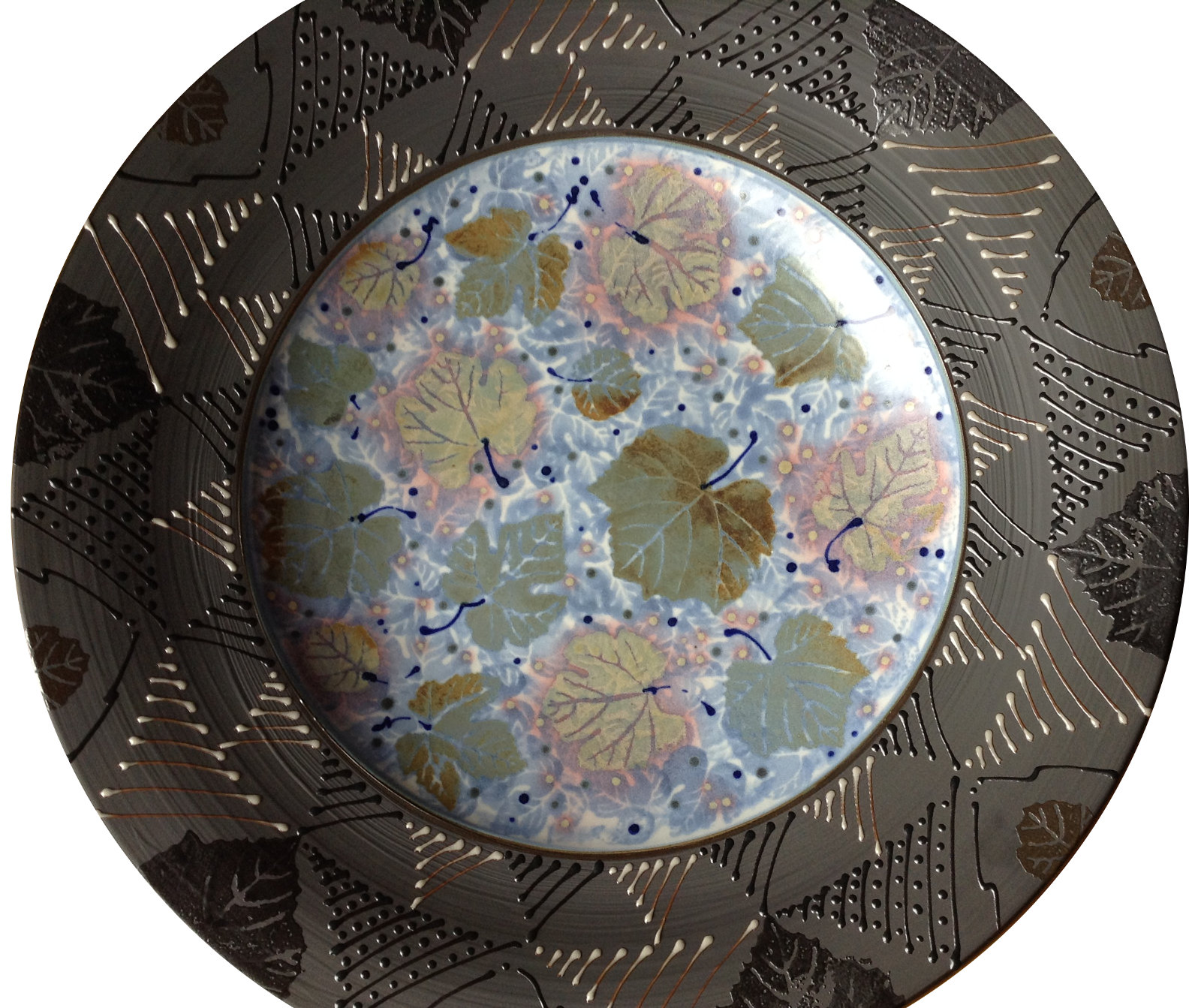

Gallery

Porcelain mugs fired at cone 10R. Pure Alberta Slip as-a-glaze outside. The liner glaze is G1947U (employing Grolleg Kaolin for the left two mugs) and EPK for the other.

Safety Data Sheet

Click here for web view.We Are Rationalizing Our Product Line

Plainsman manufactures bodies by grinding and pugging clays that we mine (native bodies) and by batch mixing bagged minerals and materials that we import (refined bodies). We stock about 10,000 boxes of 50+ clays (some in multiple stiffnesses) and need to reduce the warehousing and production burden of small-run bodies and remove obsolete and legacy products. For bodies being discontinued: We have migration paths and can assist with issues. Some changes involve increased cost. In certain cases you might consider having us custom-mix a body so you can continue to get it, but please work with us on trying to adapt to alternatives first.

This product has issues

- This body is too similar to others that are superior to justify its production.

- A legacy body recipe that predates newer and better materials.