3D Silty Clay

Description

Medium to high temperature, silty, low plasticity, light tan firing, clean native stoneware. It is mined from our Ravenscrag, Sask. quarry.

3D is a high-quality body ingredient. It contains natural feldspar and quartz (so bodies based on it need no silica or feldspar). It vitrifies well before 10. It is the cleanest (lowest in particulates and oxides of iron) and most consistent raw material we have. In the raw lump form, 3D clay weathers and slakes very readily. It is suitable as a filler where the other ingredients produce too much plasticity. It is suitable as a body base, the majority ingredient if accompanied by quality plastic clay.

Process Properties

95% 3D and 5% bentonite produces a body with good plastic workability that fires pinhole and glaze-defect-free in our drop and hold firings. By itself, it dust-presses well. It works well with additions of low temperature iron-bearing clays (like Redart) and responds well to small feldspar and talc additions to achieve maturity from cone 5-8.

3D is also an alternative to sand or grog as an addition to bodies where plasticity needs to be cut and drying properties improved (without compromising vitrification).

3D opens up the internal pore structure in the dry body matrix, this helps channel water out during drying.

Firing

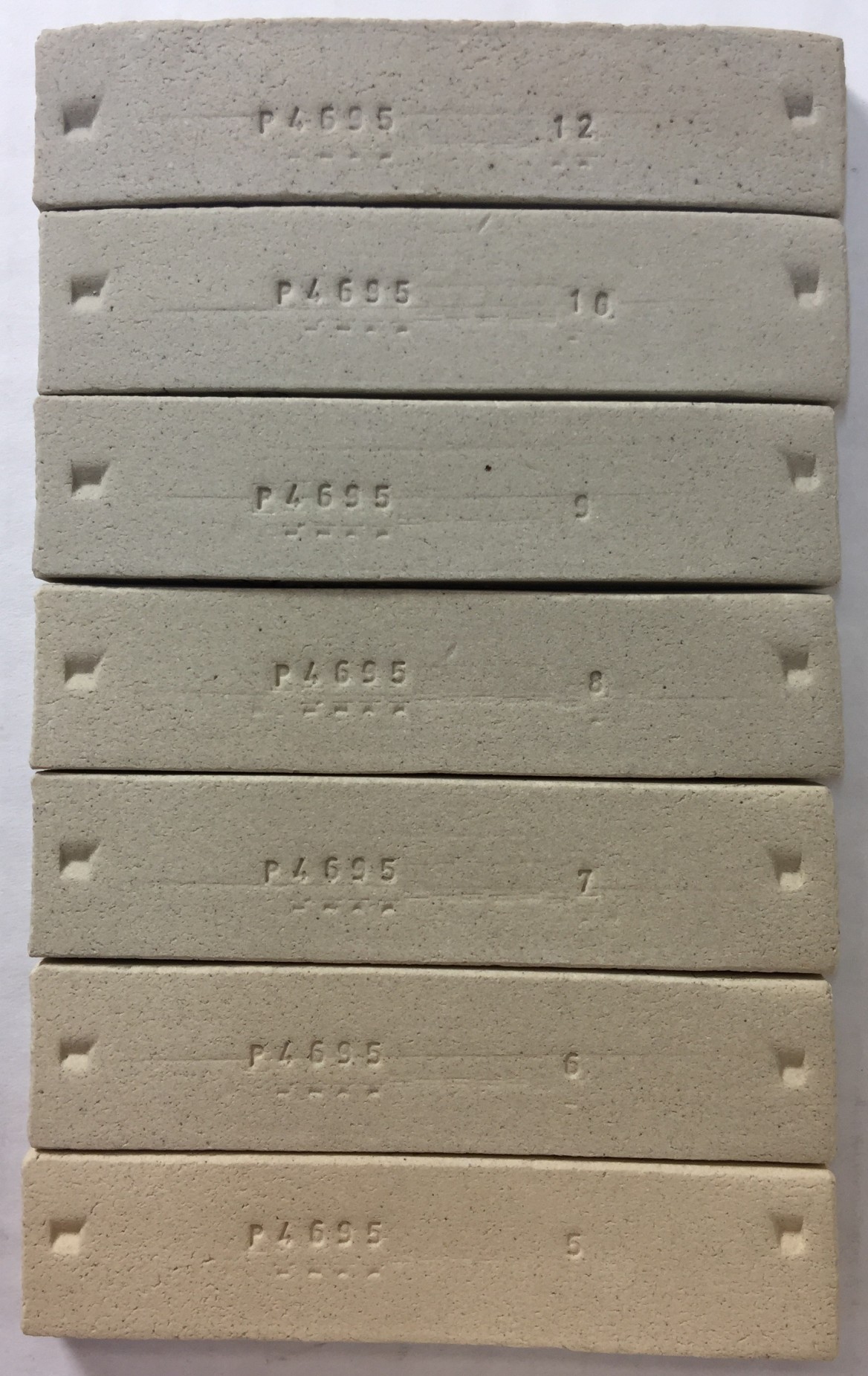

325mesh 3B and 3D fired bars. 3B ones are fired from cone 8-2 (top to bottom), the 3D ones from cone 9-3 (top to bottom). The 10% added Nepheline Syenite in the 3B reveals its iron content (firing tan to brown at cone 6). 3D, by itself, is a dense stoneware by cone 6, firing considerably whiter than 3B.

3D burns light buff in oxidation, increasing to grey-buff as toward cone 10. It fires with less reduction speckle and to a lighter buff color than any other native naturally-fluxed material we have.

Glazing

Because 3D is low in gas-producing particles, glazes fire with fewer surface defects (e.g. pinholes, blisters). In fact, even the unground, slaked material produces clean glaze surfaces. Minimal processing is needed to make the lump form useful.

Recipe

This material is good base for medium and high temperature body recipes. It can be the majority ingredient because it contains natural feldspar and quartz, so it only needs a plastic clay addition. For medium temperature, only a little feldspar or talc is needed. If it is processed to a finer particle size (by air separation or wet sieving) plasticity increases significantly (to the point that it can be used 100% to produce a cone 8 stoneware).

To see some example bodies that demonstrate the amazing possibilities of this material, plus more technical information, please click here.

Physical Properties

Drying Shrinkage: 4.5-5.5% Drying Factor: B110

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0.0-0.6% 48-65 (300-210 microns): 0.5-1.0 65-100 (210-149 microns): 0.5-1.5 100-150 (149-106 microns): 1.0-2.5 150-200 (106-75 microns): 3.5-5.5 200-325 (75-45 microns): 5.0-8.0

Fired Shrinkage:

Cone 6: 5.5-6.5% Cone 8: 5.5-6.5 Cone 10: 6.5-7.5 Cone 10R: 6.5-7.5

Fired Absorption:

Cone 6: 3.5-4.5% Cone 8: 2.0-3.0 Cone 10: 0.3-0.9 Cone 10R: 0.2-0.7

Chemical Analysis

BaO 0.4 CaO 0.2 K2O 2.6 MgO 0.5 Na2O 0.1 TiO2 0.6 Al2O3 16.3 P2O5 0.0 SiO2 71.5 Fe2O3 1.1 MnO 0.0 LOI 6.6%

Gallery

This mug is made from 100% 3D. It was screened to 325 mesh, this produces a dense stoneware that is smoother even than refined porcelains. By cone 8 it fires to porcelain density. Wet processing to 325 mesh is relatively easy since the material is naturally very fine, about 10-20% oversize is lost in this process.

M340 with transparent glaze (G2926B) and Alberta Slip GA6-B glaze (with 2% added iron oxide on the left and as-is on the right).

How is it possible for the same body to work well at both cone 04 and 6! White cone 04 bodies are not vitreous and strong and neither is this. But it is plastic, smooth and fits common low fire glazes. How? 15% Nepheline Syenite (also 50% Plainsman 3D, 35% ball clay and 3% bentonite). The unmelted nepheline particles impose their higher thermal expansion on the fired ceramic. Spectrum 700 clear glaze does not craze and does not permit the entry of water (the mug is glazed across the bottom and fired on a stilt). The mug on the right is made from the same clay, it has been fired ten cones higher, cone 6! Here the nepheline is acting as a flux, producing a dense and very strong stoneware (with G2926B, GA6-B glazes). This is incredible! One note: This cannot be deflocculated and used for casting, soluble salts in the 3D gel the slurry.