F100

Description

White talc body with fine silica sand grog. It is mix of two ball clays, 35% talc, and 15% of a blend of two grades of fine silica sand. Fine, white-firing and excellent for detailed modelling and hand building.

News

We no longer produce this but you can make your own by wedging in sand and/or grog to our Snow body. An advantage of this approach is better glaze fit than was afforded by F100.

Process Properties

Talc/Ball clay bodies tend to be very plastic and slick and have excellent drying properties (although its dry strength is fairly low). This material has added silica sand to further improve drying. F100 is an excellent throwing clay even for large pieces. It is a little rubbery and can be sticky if soft (i.e. difficult to cut off the hump, peel off boards). The fine sand that can be abrasive against the wheelhead but is not otherwise detectable during throwing.

Firing

This body must be dried completely before firing, especially if pieces are thick. Early stages of firing should be slow to allow all water to escape (because this has such a high percentage of ball clay).

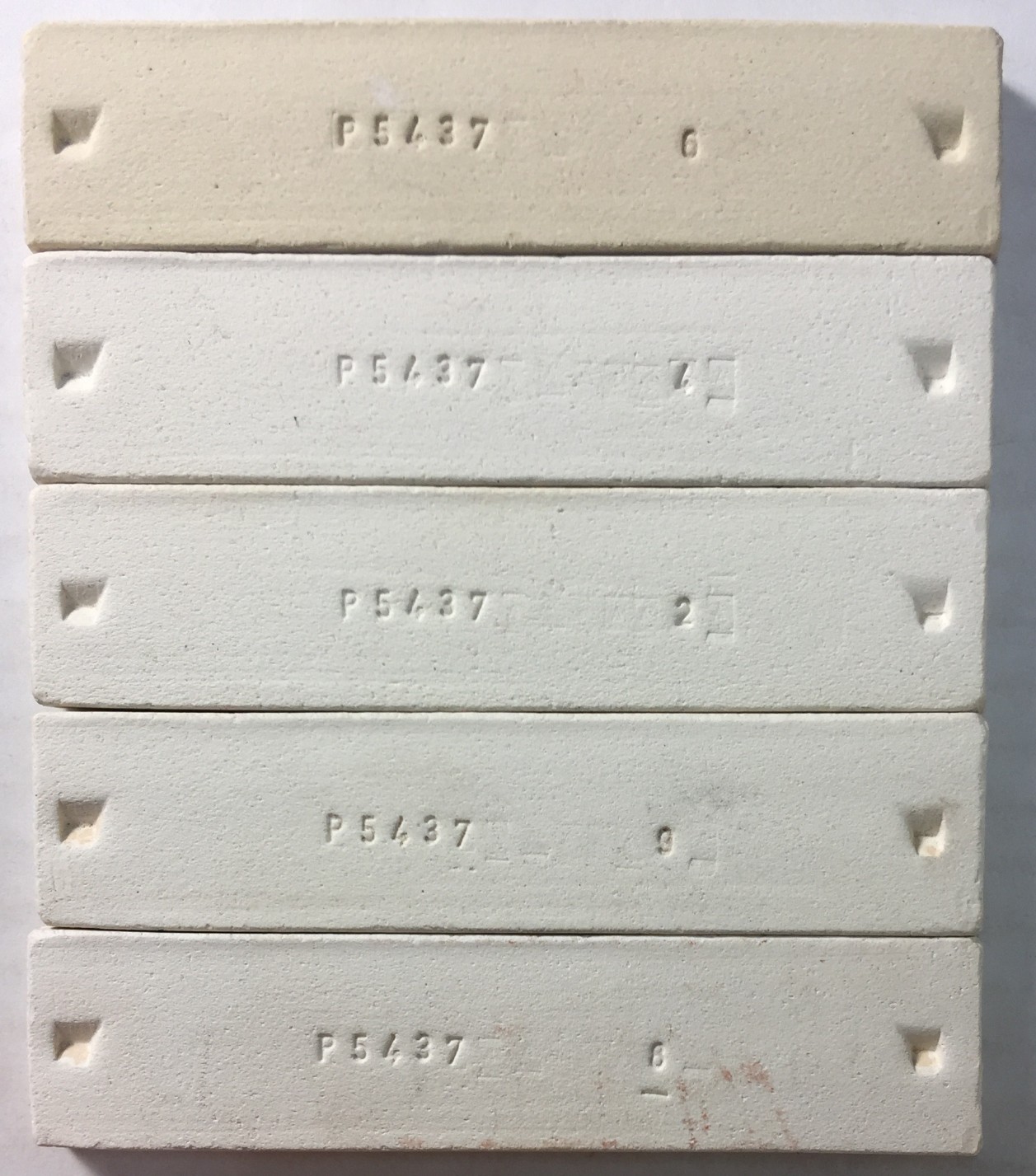

Fired bars are the classic cone 04 talc body color, however the texture is not quite smooth, due to the fine aggregate. The color shifts from white-buff to yellow-buff above cone 4. This body does not melt at cone 6 as do some talc bodies, however ware will be brittle if fired to that temperature.

This body has a high porosity at cone 06, fire as high as your glazes will take, cone 04 if possible. If you can fire to cone 03 strength will be improved even further.

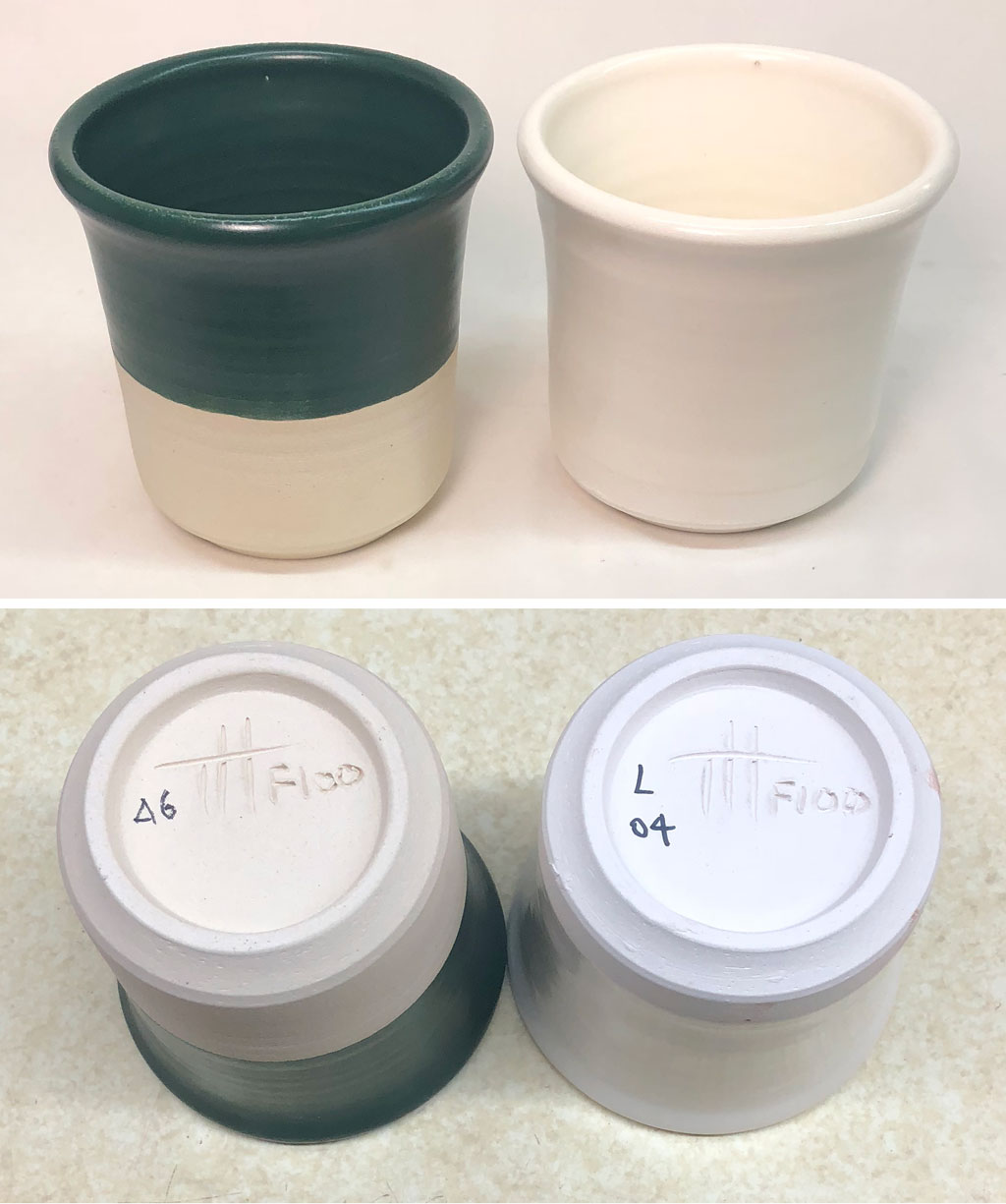

Left: F100 fired at cone 6 with G2934 base matte glaze (green stained). Right: Fired to cone 03 with G2931L clear base glossy glaze.

Glazing

The sand content makes this body unsuitable for many types of functional ware, because it produces a gritty texture on rims and edges. This means that glazes need to be applied thickly, and, in order for them to not craze or shiver, their thermal expansions must match the body well. We do not have glaze recipe recommendations for this body, you will need to experiment to find something available to you that works.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 4.5-5.0% Dry Strength: n/a Drying Factor: B110 Water Content: 20.0-21 (Mar 99) Dry Density: 1.95

Sieve Analysis (Tyler mesh):

+48 (300 microns): 0.0-0.6% 48-65 (300-210 microns): 0.4-0.8 65-100 (210-149 microns): 2.5-3.5 100-150 (149-106 microns): 2.0-3.0 150-200 (106-75 microns): 5.5-7.5 200-325 (75-45 microns): 7.0-10.0

Fired Shrinkage:

Cone 04: 1.0-1.5% Cone 2: 2.5-3.5 Cone 3: 2.5-3.5 Cone 5: 2.0-3.5

Fired Absorption:

Cone 04: 14.5-15% Cone 2: 10.0-11.0 Cone 3: 9.0-10.0 Cone 5: 10.0-11.0