Home

Glazes, Engobes

Zero3 Cone 04-02 Transparent Glaze

Description

This recipe is actually three. All produce an ultra-transparent base but they differ in thermal expansion. That enables people to deal with crazing and shivering, which are much more common at low temperatures. The median recipe is G2931K, it was originally designed to work with the Zero3 system (engobe, stoneware and porcelain fired at cone 03). It is about firing a little higher (cone 03) to get a lot better strength and durability. It works well on L212, L215.

G2931L melts well at cone 04, it is the low expansion adjustment to fit Buffstone. G2931H is the high expansion version to fit high talc bodies (like L213, L212).

Process Properties

All low temperatures it is customary to buy premixed glazes. So researching, studying and mixing your own may be a big departure from your normal. But to produce quality and durable ware at low fire it is very important that the liner glaze at least, fits the body without crazing or shivering. And that you fire to the highest practical temperature. The base glaze approach to ceramics has a lot of merit and costs much less. These recipes provide the opportunity for you to choose or blend a base that fits your circumstances.

Screening: We have not ball milled this product, thus it may contain some oversize particles from the constituent materials. We advise sieving the glaze slurry to at least 80 mesh.

Firing

For stronger ware we recommend firing cone 04-03. Every cone higher you can fire will dramatically improve ware strength. All low fire bodies and glazes can easily tolerate firing higher. The chemistry of this recipe produces a more durable glass than commercial cone 06 glazes (they sacrifice hardness and durability to melt at a lower temperature).

For much better and defect-free surfaces, use the 04DSDH drop-and-hold slow-cool firing schedule.

If you do not need strength and must fire lower (e.g. cone 06), then don't use this, use G1916Q or a commercial product.

Glazing

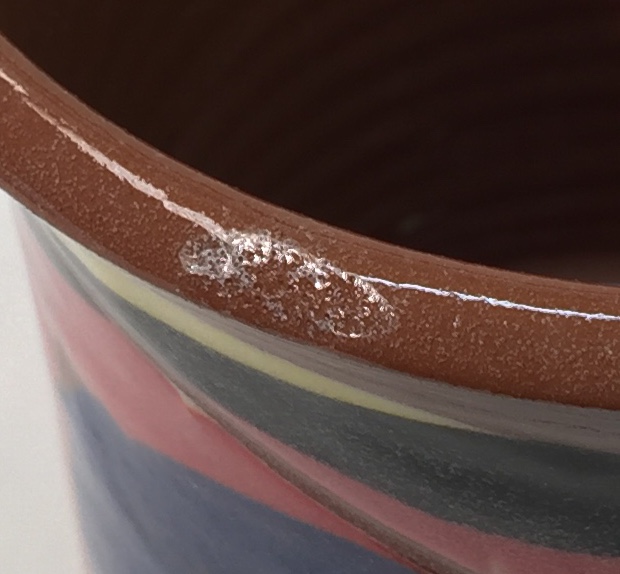

This glaze is more sensitive to thickness than most stoneware glazes. If too thin it will not be smooth, if too thick it will run during firing. Be sure that ware has been fired to the temperature for optimal porosity for glazing. If bisqued too high ware will not be absorbent enough for the glaze to stick in a sufficiently thick layer. Conversely, if ware is bisque fired too low or ware is immersed too long during dipping, the glaze will go on too thick and run during firing. If you are brushing consider just two layers. Whatever you do, we recommend a test firing to verify. Keep good records of your bisque temperature and maintain the glaze at the right specific gravity and viscosity.

The body is Plainsman L215. There is good reason to fire to cone 03 instead of 04. The underglazes work the same. The clay is stronger and a deep red color. But best of all, the glaze is more transparent because it has fewer micro-bubbles suspended in the glass. Cone 03 is also more tolerant of getting the glaze on too thick, at 04 will will turn completely milky.

Recipe

These are not available as a premixed products. For our lab information on the recipe and how to mix and use it click here.

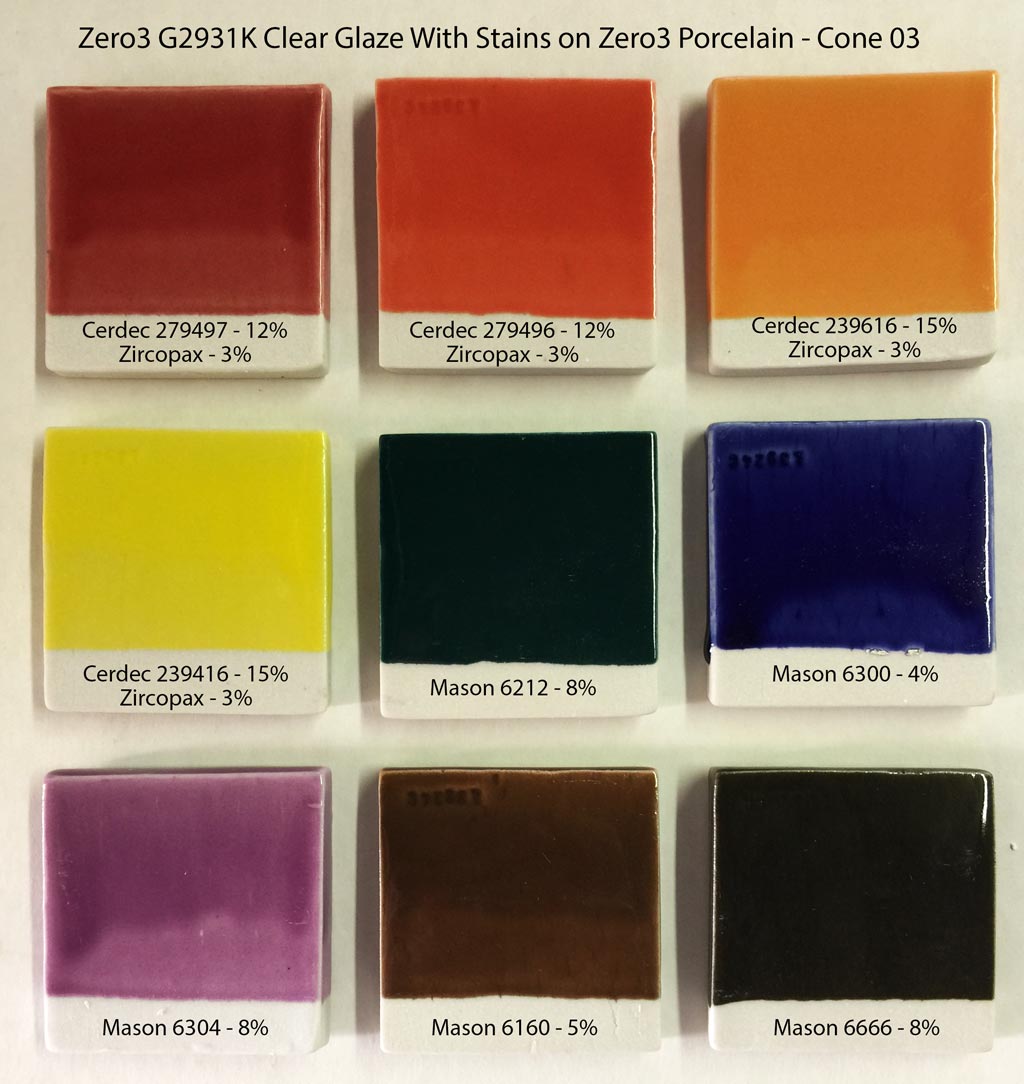

Zero3 Clear glaze with stains for primary colors, brown and black. These are 10 gram balls that have been melted down onto a tile (they thus show it very thick). The tiny bubbles are not present on glazed ware (especially if 2-3% zircon is added).

In the above images, the stains have been mixed right into the clear glaze powder to get the six primary colors. Using these primary colors you can blend almost all color you want. Lighten any color by diluting with the clear.

Thermal Expansion

Low fire glazes are much more difficult to match to the body, crazing and shivering are thus much more common than at higher temperatures. That is why we have three recipes: K, L and H. One of these will fit most bodies, if not they can be blended to fine tune fit. But there is another thing to consider if you intend to color or opacify: Adding zircon (for white) reduces thermal expansion and stains can also affect it.

Do not use the Zero3 L glaze on Zero3 stoneware or on talc bodies (like Plainsman L215, L212, L213), it shivers. This is intended, it has the very low thermal expansion needed to fit non-talc, non-vitreous low fire bodies (like Plainsman Terrastone, Buffstone).

Gallery

Zero3 Porcelain mug fired at cone 03 in 3 hours. Notice how ultra-clear the Zero3 K glaze is over the underglazed areas. No micro-bubbles. It is applied in a very thin layer. By Tony Hansen.

Zero3 Stoneware mugs decorated with underglazes and finished with G2931K ultra clear glaze. By Tony Hansen.

Buffstone and L215 with underglaze decoration and G2931 weigh-and-mix-yourself clear dipping glazes. But they are not the same. The G2931L glaze (left) has a lower thermal expansion (to slow crazing on Buffstone). The G2931K glaze fits L215 because the latter contains some talc (which raises its expansion). The L215 mug has survived a 300F-to-ice-water thermal shock without crazing or shivering. If you switch the glazes the Buffstone mug would craze it and the L215 would shiver it off in flakes.

L212 underglaze decorated mug fired at cone 03. Outside glaze is G2931H clear. The liner glaze is Crysanthos SG001 white.

Zero3 Porcelain, Zero3 base glaze with 10% inclusion stains and 2% zircopax added (the zircopax is needed to prevent micro-bubbles and surface dimples). The liner glaze is Zero3 K transparent.

Buffstone, L212 and L213. Each has its own clear glaze. G2931L, G2931K and G2931H.

L is low expansion (for zero-talc porous bodies like Buffstone). K is intermediate (for moderate-talc bodies like L215, Zero3 stoneware and porcelain). H is high-expansion (for higher-talc bodies like L212, L213).

Buffstone and L215 with underglaze decoration and G2931 weigh-and-mix-yourself clear dipping glazes. But they are not the same. The G2931L glaze (left) has a lower thermal expansion (to slow crazing on Buffstone). The G2931K glaze fits L215 because the latter contains some talc (which raises its expansion). The L215 mug has survived a 300F-to-ice-water thermal shock without crazing or shivering. If you switch the glazes the Buffstone mug would craze it and the L215 would shiver it off in flakes.