MNS

Description

Mother Nature's Stoneware, MNS, is a pure mined sedimentary clay called "3D" that Plainsman Clays mines in a quarry in south western Saskatchewan. It fires to a dense stoneware at cone 6. This does not fire as dense as MNP and is not as plastic, but it burns whiter.

Plainsman Clays does NOT make this as a body. But you can make your own from the raw 3D lump material or 42 mesh powder. Traditional porcelains, like P300 and M370, are carbon-intensive, made from highly processed industrial minerals transported across North America and even over oceans. Making your own MNS is the ultimate low-carbon way to have a vitreous stoneware body. Of course, you must live near to the Plainsman plant to be able to buy the raw material and have a little equipment to make it (see below).

Preparation

3D is a fine silty clay. It has fairly low plasticity. Thus, unless you are sieving it to 325 mesh, an addition of bentonite is needed to impart the needed plasticity (experiment with 1-5%). More bentonite gives more plasticity but also increases the drying shrinkage.

To achieve finer particle sizes (for highly refined ware) simply slurry up the powder, sieve it, and dewater it on the plaster surface until the desired stiffness is achieved. Although it is possible to hand-sieve the material for sizes up to about 80 mesh, a sieve shaker is needed for finer sizes (140-325 mesh). For hand sieving it is better to process the slurry at a higher water content, settle it in buckets and pour off excess water the next day. 100 mesh is practical to make most things, up to 98% should pass the screen. At 80 mesh some fine specks may show through glazes. Using a sieve shaker, processing at 150, 200 or even 325 mesh is possible, each upsize will generate more oversize (20% at 325 mesh).

Firing

MNP fires as dense and as stoneware-strong at cone 6, porcelaneous by cone 8. Mother Nature included just the right amount of feldspar to mature it at cone 6-7.

Physical Properties

Drying Shrinkage: 5.5%

Fired Shrinkage:

Cone 5: 5.5% Cone 6: 6.5 Cone 7: 7.0

Fired Absorption:

Cone 5: 5% Cone 6: 2.5 Cone 7: 0.5 Cone 8: 0

Gallery

This mug is made from 100% 3D. It was screened to 325 mesh, this produces a dense stoneware that is smoother even than refined porcelains. By cone 8 it fires to porcelain density. Wet processing to 325 mesh is relatively easy since the material is naturally very fine, about 10-20% oversize is lost in this process.

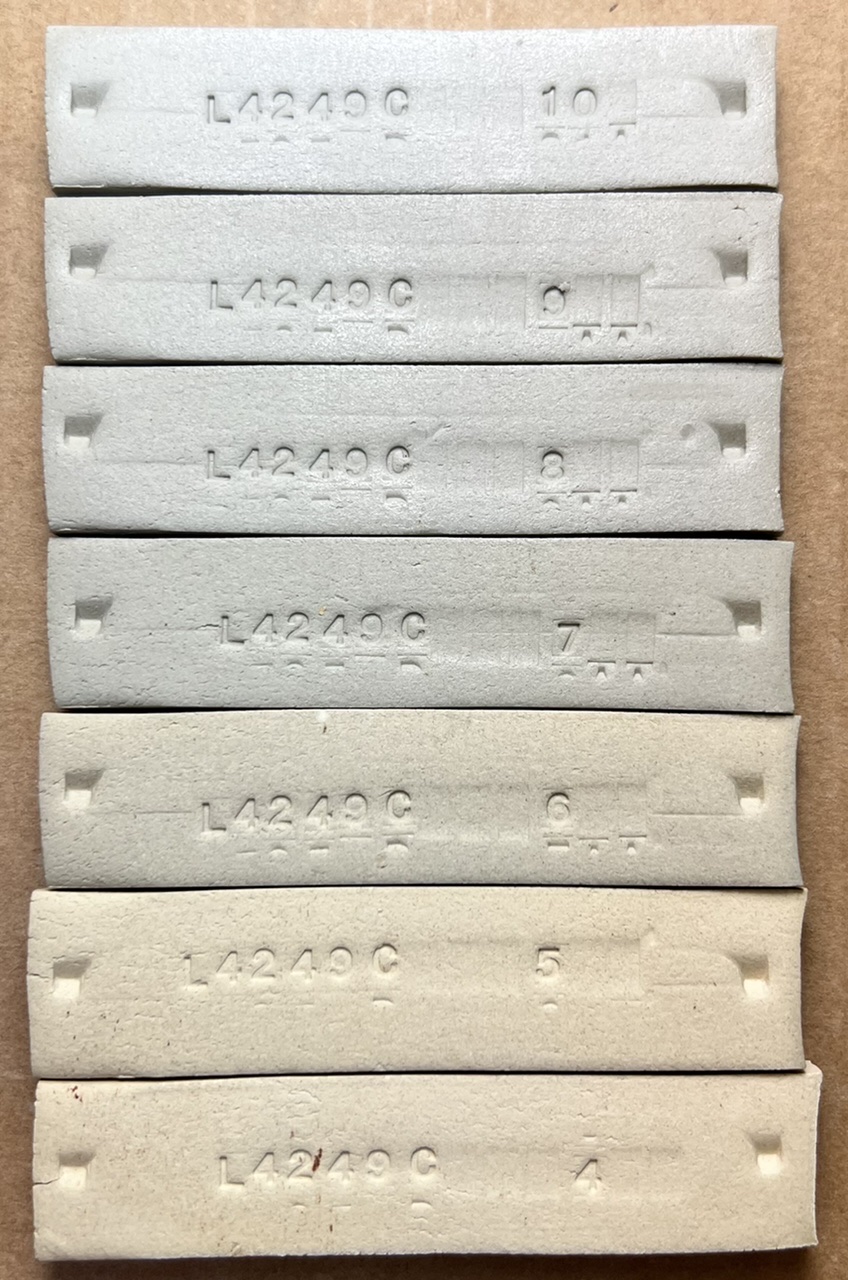

L4208C is a body made using a high percentage of 3D. For this one the 3D has been sieved to 200 mesh. This is a stunning piece, strong as steel, clean burning. Inside glaze is G2926B, outside is G2934Y with orange stain.

200 mesh pure 3D fired at cone 10R with Ravenscrag talc matte GR10-C glaze. Although 3D reaches zero porosity density by cone 8 it fires stable to porcelain density at cone 10R (if processed to 200 mesh or finer to avoid bloating). Tiny reduction specks are visible on this so 325 mesh would be required for a porcelain smooth surface.