H443

Description

High temperature, slightly textured, plastic, semi-vitreous, iron-brown speckled, general purpose, native body for dark iron reduction fired stoneware.

H443 is a classic mottled-brown reduction speckled stoneware. Unlike H440, it generally fires with no red hues. H443 is not a vitreous body, it stops short of complete maturity to retain a variegated earthy color. It is best suited for decorative pieces large or small (vases, bowls, planters, etc.).

Process Properties

H443 is a reddish brown in pugged form and made totally from a blend of Plainsman native stoneware materials. It has good plasticity (exellent if it is stiffer) and exhibits only a slight sandy texture during throwing (by virtue of kaolinized sand in its recipe). H443 has an excellent distribution of clay particle sizes in the plus 325 mesh range and these are a factor in its fast drying and high dry density and strength. However, even though H443 dries well it does have a fairly high drying shrinkage and thus care and attention are necessary to be sure larger pieces, especially flat plates, shallow bowls, and sculptural ware are dried evenly.

Firing

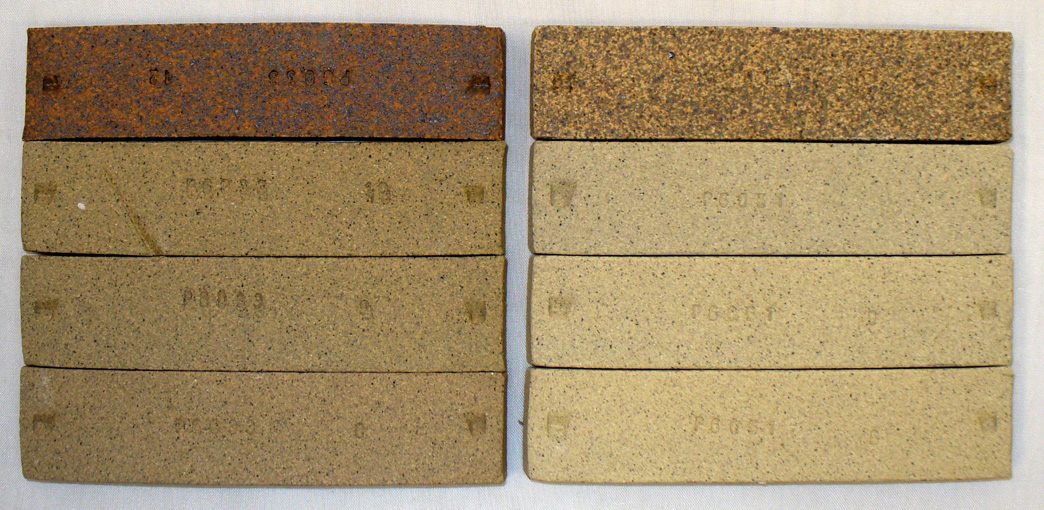

These test bars (left to to right) compare H440 and H443 at cone 10R (top) and cone 10, 8 and 8 oxidation.

H443, like other iron reduction bodies, depends on stopping short of being vitrified to achieve the characteristic warm brown coloration. H443 has been formulated so that cone 10R is at its transition point from a toasty brown to a dark brown. When fired just right the surface is a patchy network of darker brown vitrified areas beginning to invade the lighter colored matrix. If over-fired or over-reduced the surface will burn a dark solid brown. If you wish to fire at a lower reduction temperatures, good color is possible as low as cone 8.

H443 contains some iron stone concretion particles that melt vigorously in high temperature reduction and blossom on the bare clay or bleed up through glazes. The degree to which these speckles melt and develop is dependent on the amount of reduction imposed.

H443 can be fired in oxidation, but its color is dramatically lighter (a leather to greenish brown from cone 6 to 10) and the speckle is much finer. If overfired H443 will tend to blister and bloat sooner in oxidation because the coarser particles in the clay are much more active in producing gaseous by-products during decomposition.

Glazing

Since H443 is a dark stoneware it readily bleeds its iron into glazes and colors and significantly colors them. This will especially be the case in reduction firing, brightly colored glazes will not be as vivid as they would be if used on porcelain. On the other hand, this effect will enhance the appearance of earthtone and variegated glazes.

H440 has a reasonably high porosity so the fired body will tend to absorb water. Thus it is important that glazes not be crazed to assure that ware is water tight and will not be susceptible to moisture expansion. Strength can be significantly impacted if glazes do not fit properly (use an ice water:boiling water immersion test to make sure).

Glaze Recipes

Commercial brush-on glazes: They may or may not fit our clays (check for glaze fit using a BWIW test or similar). For brightly colored glazes (especially with layering) do a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Mixing your own glazes is practical (with our clear guidelines even beginners can make dipping glazes that go on silky smooth and evenly and dry in seconds). If you already do this using recipes from the web, be careful. High-feldspar glazes (having more than about 35%) often craze. Some recipes rely on high melt fluidity to encourage crystallization and variegation (often because of inadequate SiO2 and Al2O3 or containing Gerstley Borate or Frit), view these with suspicion for leaching and cutlery marking; test them well (also test the additionless versions). Be suspicious of any glaze not having good documentation.

Consider using our G1947U glossy or G2571A matte base recipes, just add colorants, opacifiers, variegators (you will find links to much more information and pictures about these). If you have a recipe that is troublesome, consider transplanting its opacifiers, colorants and variegators to these bases instead. http://ravenscrag.com and http://albertaslip.com also have many recipes that work well on porcelains.

Crazing: Functional ware must remain craze-free (crazing is unsanitary and drastically reduces ware strength). Even though ware may not be crazed out-of-the kiln it may do so with time. Do cycles of a boiling water:ice water immersions (BWIW test) on a piece to test glaze fit (by stressing it to bring out any crazing or shivering tendencies).

Thixotropy: If you want the best application properties for one-coat dipping, consider creating a thixotropic slurry. Thixotropic glazes are creamy because they have been thinned and then gelled by the addition of a flocculant.

For slip decoration and engobes be careful to match the fired shrinkage of the slip with the body. Where we do not recommend a specific engobe recipe, consider one based on the body itself. Add 2% VeeGum or Bentonite (the extra stickiness helps it adhere well to leather hard ware). Be careful about adding fluxes (e.g. frit), this increases fired shrinkage creating a mismatch with body that can cause flaking (and can compromise engobe opacity).

If you want to develop and mix your own glazes and engobes consider getting an account at insight-live.com. You can organize a methodical development program and adopt better methods of testing (e.g. melt fluidity, thermal stress, slip-fit tests).

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.0-6.8% Dry Strength: n/a Water Content: 20.5-21.5% Drying Factor: C120 LOI: 6.5-7.5 Dry Density: n/a

Sieve Analysis (Tyler mesh):

+48: 0.0-0.5% 48-65: 1.0-3.0 65-100: 5.0-7.0 100-150: 3.0-5.0 150-200: 4.0-7.0 200-325: 7.0-10.0

Fired Shrinkage:

Cone 8: 5.2-6.2% Cone 10: 5.5-6.5 Cone 10R: 5.5-6.5

Fired Absorption:

Cone 8: 4.5-6.0% Cone 10: 3.0-4.0 Cone 10R: 2.5-3.5

Chemical Analysis

BaO 0.5 CaO 0.4 K2O 1.6 MgO 0.5 Na2O 0.2 TiO2 0.8 Al2O3 18.9 P2O5 0.0 SiO2 66.1 Fe2O3 2.5 MnO 0.0 LOI 8.6%

Gallery

A cone 10R planter made from H443. In this firing it has a reddish tone (the color varies according to reduction). By Tony Hansen.