Ravenscrag Slip

Description

Fine grained low plasticity cone 10 melting silty clay. Ravenscrag Slip is a blend, its principal ingredient is mined from a large deposit near Ravenscrag, Saskatchewan, Canada. It was originally developed as an almost-complete base cone 10 glaze (it is feasible to use 'as is' on either green or bisque fired ware, to achieve a light colored silky matte surface). The material can be viewed as a 'plastic feldspar' that provides good melting and excellent slurry properties. With frit additions, this material is also very useful in cone 6 glazes.

All of these mugs are made from glazes whose major component is either Alberta Slip or Ravenscrag Slip. They are all fired at cone 10R.

News

November 2022: We began producing this material at 60 mesh, starting with run #7048. This greatly streamlines our ability to keep up with demand. We recommend sieving glazes through 80 mesh maximum, this removes particles that could otherwise cause roughness on contour edges of fired glazes. Only one pass is needed.

Process Properties

Ravenscrag Slip is a silty clay and has good application properties (when used pure and not applied too thickly). However, when glazes employ a high percentage of Ravenscrag Slip they will crack on drying (and crawl on firing), it is important to roast a portion of the powder (e.g. the GR6-A recipe). For use as a base coat or in multi-layer applications consider adding CMC gum also.

Glazes are most often prepared using the traditional method of simply adding water until the desired consistency is achieved (rather than targeting specific gravities and conditioning with flocculants). No flocculant chemical additions are needed, it applies well across a range of viscosities (although more viscous slurries can create overly-thick applications).

Left: Raw Ravenscrag Slip powder. Right: Roasted at 1080F. This is a silty clay, thus it has a relatively low drying shrinkage. Where a glaze is applied thickly or the percentage of Ravenscrag is high, shrinkage cracks (which produce crawling during firing) can occur. We recommend a mix of roast and raw material in recipes. Roasting the Ravenscrag powder at 1000F greatly reduces the shrinkage. Use a firing rate and hold-time-at-1000F appropriate for the wall thickness and size of your bisque vessels (e.g. 500F/hr and 30 minutes for thin-walled small vessels, slower and longer hold for large ones). If any of the powder within is black, increase the hold time for the next firing. Adjust proportions as needed (more roast if the glaze cracks on drying or more raw if it is drying too powdery or not bonding well).

The roasted material has a weight-loss of about 3% on firing (vs. 9% for the raw powder). This difference can be ignored in most cases. But, to be more precise, use 3% less of the roasted powder (multiply the amount by 0.97). For example, suppose you need 1000 grams of a 50:50 raw:cacline Alberta Slip mix for a glaze recipe. Use 500 raw and 500*.97=485 roast.

Since Ravenscrag Slip is a siltly material it does not work well for burnishing.

Firing

Ravenscrag Slip is the opposite of Alberta Slip: The latter is a low-melting, plastic, and dark burning; Ravenscrag Slip is higher-melting, non-plastic, and light burning. It flows to a silky-matte surface at cone 10.

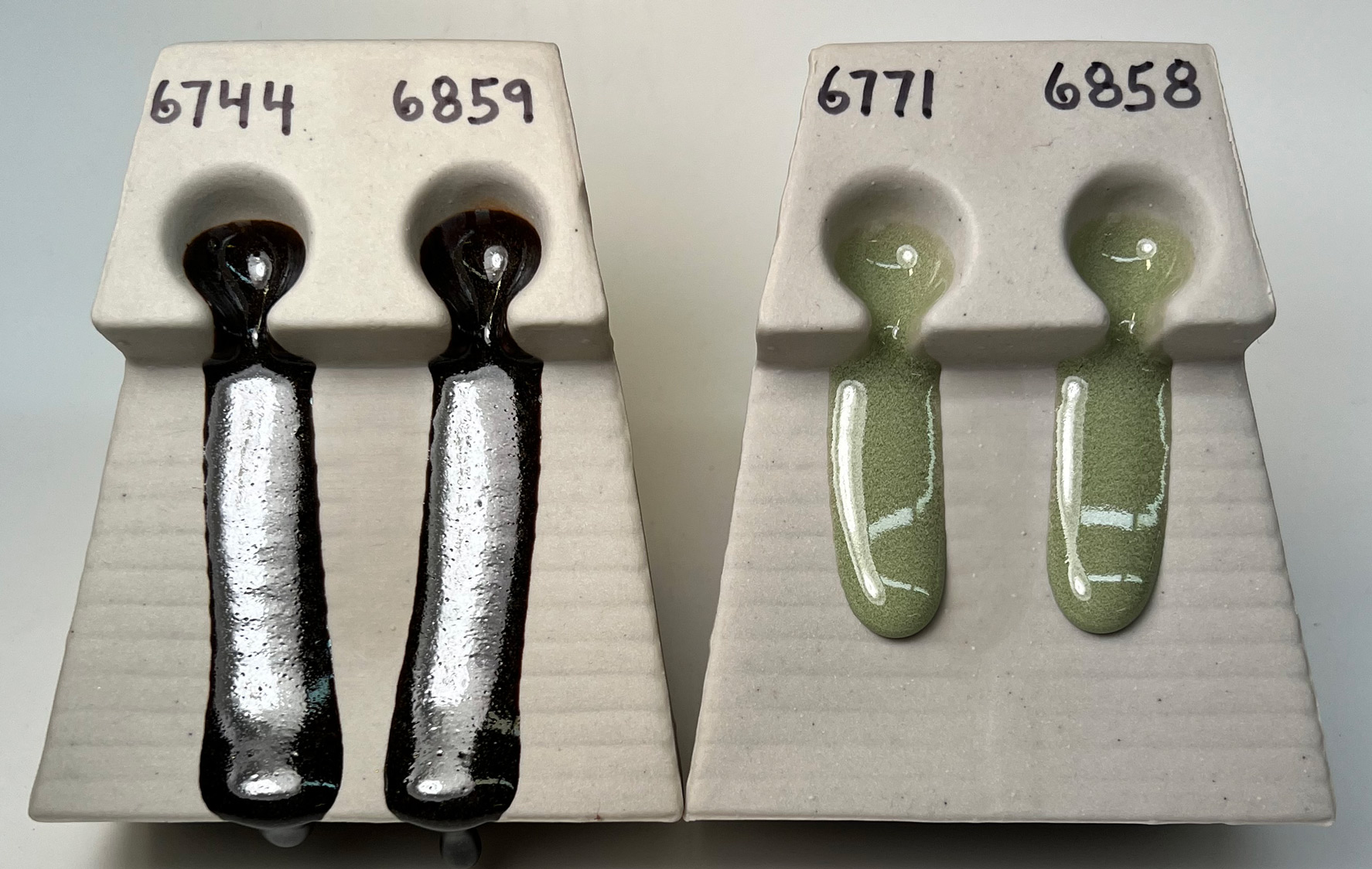

Melt flow tests of two runs of Alberta slip and Ravenscrag Slip (both fired at cone 10R). These demonstrate the kind of consistency we have been able to achieve over many years.

Adding about 20% Ferro 3134 frit will produce a base transparent glaze for cone 6. You can add colorants (i.e. stains, metal oxides), variegators (i.e. 5% rutile), and opacifiers (i.e. 10% Zircopax) to create almost any effect.

Since it is basically a clay material a significant amount of gas is generated during decomposition during melting. If not fired high enough and not fluxed adequately very thick layers could tend to form unbroken bubbles in the glaze layer.

Glaze Recipes

Common Recipes for Cone 6

- Base Transparent - GR6-A

- Base Transparent - G2936 (low thermal expansion)

- Opaque Ivory - G2936B

- Rutile Blue - GR6-M

- Oatmeal - G3933EF

- Light Blue Matte - G2850M-C

- Kat's RC Matte - G2851D

- Light Blue - MRG6B

- Teal Blue - G2850P

- Brown Gold Matte G2851H

- Light Blue-White Matte - MRG6G

- Matte Blue - G2851A

- Floating Blue - G2851AB

Common Recipes for Cone 10R

Chemical Analysis

CaO 10.1 K2O 3.0 MgO 1.7 Na2O 0.5 TiO2 0.4 Al2O3 12.6 SiO2 61.8 Fe2O3 0.8 LOI 8.8%

Gallery

Ravenscrag Slip is the magic behind this amazing glaze recipe. We are now recommending the G3933EF recipe for a cone 6 oatmeal. The Ravenscrag Slip base gives this multiple advantages over the previously recommended G3933A recipe (which used a mix of our G2926B and G2934 recipes).

Ravenscrag Slip really shines in its ability to produce a good floating blue glaze at cone 6, this is GR6-M. The speed of cooling in the kiln affects the appearance (faster cool gives better blue). The left M340 mug was fired using our drop-and-soak PLC6DS firing schedule, the other, also M340, with the slow-cool C6DHSC schedule.

This is GR6-L, the standard GR6-A Ravenscrag Slip cone 6 base recipe + 10% chrome tin stain (the body is Midstone, the inside glaze is G2926B, the firing schedule is C6DHSC).

Ravenscrag GR10-C silky matte over L3954N black engobe on H550. Fired at cone 10R. GR10-C is just 90% Ravenscrag Slip and 10% talc.

Plainsman H450 (buff stoneware) mugs fired at cone 10R with pure Alberta Slip on the outsides, G1947U transparent (left) and pure Ravenscrag Slip liner glaze. By Tony Hansen.

This is 100% Alberta Slip (outside) and 100% Ravenscrag Slip liner glaze. White stoneware H450 clay fired to cone 10R. Both glazes have been made using a blend of calcine and roast (60:40 and 50:50). By Tony Hansen.