MNP

Description

Mother Nature's Porcelain, MNP, is a pure mined sedimentary clay called "3B" that Plainsman Clays mines in a quarry in southwestern Saskatchewan. It is a natural mix equivalent to about a 35:65 mix of ball clay and feldspar (with some iron staining) and is fine-grained naturally (apart from particulate impurities). It fires porcelain density at cone 6 (although not buff to tan burning).

Plainsman Clays does NOT make this as a body. But you can make your own from the raw lump material or 42 mesh powder by wet processing. Traditional porcelains, like P300 and M370, are carbon-intensive, made from highly processed industrial minerals transported across North America and even over oceans. Making your own MNP is the ultimate low-carbon way to have a porcelaineous body. Of course, you must live near to the Plainsman plant to be able to buy the raw material and have a little equipment to make it (see below).

Preparation

The finer you are able to sieve the 3B crude clay, the more plastic, smoother and iron particle free it will be. 95% should pass a 200 sieve and 90% a 325. Plasticity can be augmented with a small bentonite addition (e.g. 1-3%).

To process it, slurry up the powder, sieve it, and dewater it on the plaster surface until the desired stiffness is achieved. Although it is possible to hand-sieve the material for sizes up to about 80 mesh, a sieve shaker is needed for finer sizes (100-325 mesh). At 100 mesh is practical to make most things. At 80 mesh, some fine specks may show through glazes.

Process Properties

On the wheel, this feels like porcelain - but throws better, it is super plastic but not at all sticky. But unlike porcelains made from commercial minerals, MNP has the drying properties of a stoneware (because of its high dry strength). Mother Nature has done a superb job of mixing the silica, feldspar and clay!

MNP is the best choice for making dark-colored porcelains, it requires less stain (e.g. black, brown, dark blue).

Firing

MNP fired test bars from cone 8 (top) to cone 4 (bottom). The bars on the left are the standard 42 mesh pugged material we supply (with barium carbonate added to precipitate its high soluble salt content). The ones on the right were made using a slurry up process, sieved to 325 mesh.

200 mesh MNP fires to zero porosity at cone 6. Add 5-10% feldspar or nepheline syenite if maturity is needed at cone 4-5.

Glazing

MNP has enough natural quartz so that almost any glaze that fits our other bodies will fit this.

Physical Properties

These are the properties of the 42 mesh material. The finer you screen it the more vitreous it will fire.

Drying Shrinkage: 6.5% Dry Strength: n/a Drying Factor: C120 Dry Density: n/a

Sieve Analysis (Tyler mesh):

+65: ~0.5 65-100: ~2.5 100-150: ~2.0

Fired Shrinkage:

Cone 4: 6.0 Cone 5: 6.5 Cone 6: 6.5 Cone 7: 6.5

Fired Absorption:

Cone 4: 1.5 Cone 5: 1.0 Cone 6: 0.5 Cone 7: 0

Gallery

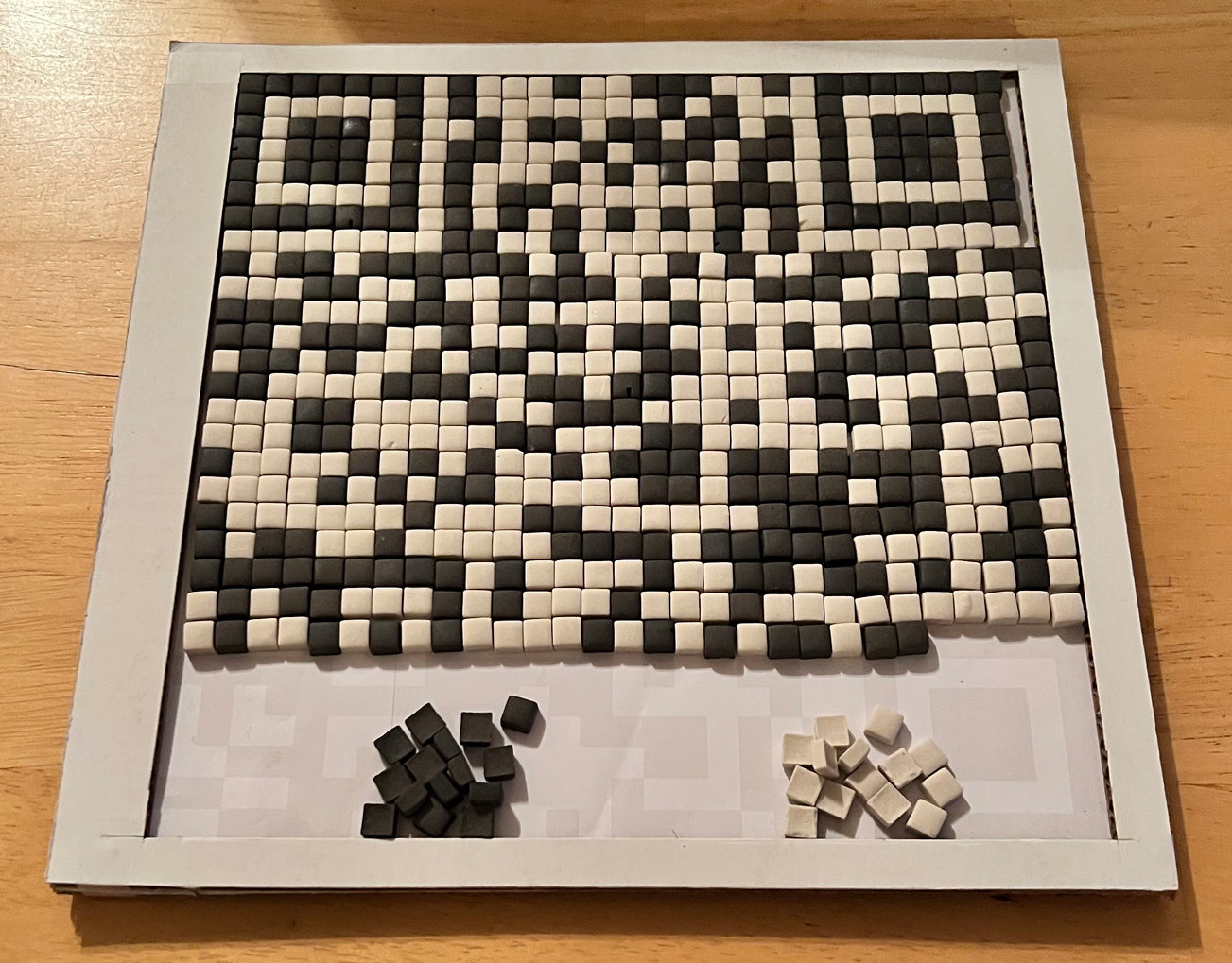

These are Plainsman MNP 100#, MNP and M370 50:50 mix and MNP 80# fired at cone 5 C5DHSC schedule. Inside glaze is L3500G, outside is a 85:15 G2934 and G2926B mix with 6% Mason 6600 black stain added. The pieces have the strength of a porcelain.