Coffee

Description

Mid-Fire Coffee Black is made from a base similar to H550 with a 10% addition of burnt umber (a calcined naturally occurring pigmented clay). The umber colors the fired body and matures it enough for functional ware at cone 6. Coffee Clay is smooth and easy-to-throw.

Another option to get a blacker body

L3954B black engobe can be applied to M340, staining just the sections needed. The color is much blacker than Coffee clay. And there is no manganese and no off-gassing to disrupt glazes. Here is an example:

M340 mugs with L3954B engobe (having a Mason 6600 black stain addition). These are overglazed with GA6-C Alberta Slip Rutile blue on the outsides and Alberta Slip GA6-A amber base on the insides.

Coffee Clay with G3948A iron red glaze fired at cone 6 using the C6DHSC firing schedule. This type of glaze excels on dark burning bodies.

GA6-C Alberta Slip rutile blue looks best on dark bodies like Coffee Clay. This is fired using the C6DHSC schedule.

Coffee Clay with the GA6-B base glaze fires ultra gloss black (on the insides of these mugs). This black glaze has no added cobalt, chrome, manganese, copper, nickel or black stain - only iron oxide!

GR6-L glaze (Ravenscrag cone 6 base + Mason 6381 stain) on M340 and Coffee Clay. Fired using the cone 6 C6DHSC firing schedule.

News

We rely on the consistency of burnt umber to maintain the maturity, color and speckle development. Umber is a heavily pigmented raw clay that is maintained for staining cement, mortar and paint (for ceramics we must tolerate some variations e.g. particle size, chemistry). You may see differences in the pugged or bisque fired color from run to run, this happens when we have to change suppliers or grades of the umber product - however the fired color at cone 6 will still be normal.

Process Properties

This clay is plastic, it throws and forms well (even if soft). It generates plenty of slip on throwing and is smooth.

Coffee clay is plastic. This 6" high vessel was thrown from fairly soft material and has not been trimmed. The photo has been enhanced on the left to make it easier to see.

Being relatively high in iron pieces will heat up in a microwave. Please test to assess suitability.

Firing

To develop color Coffee clay needs to be fired to 5-6 (center bar). By cone 7 it bloats badly (as the raw umber clay begins to decompose). It is thus vital that ware is not fired past cone 6.

Chemically, Coffee clay contains approximately 1% MnO. Maximum firing is cone 6, 2200F (because beyond that manganese fumes can be released as the umber decomposes, even before that it is gassing). Use cones to verify that your electronic controller or kiln sitter is not firing beyond cone 6 (this is also important to avoid bloating). For more toxicity information please see the article Managance in Clay Bodies.

Bisque firing can be done at the same temperature as other bodies (we bisque around 1850F).

To get the best defect-free surface please consider using a drop-and-hold firing schedule, for example the PLC6DS schedule. If crystallization during cooling is not an issue, glazes will give optimum results if slow-cooled also (e.g. the C6DHSC schedule).

Coffee Clay vs M340S with white glossy glaze in a normal PLC6DS schedule. Notice the orange peel surface on the Coffee Clay, this is because gases are coming out of the body and the zircon stiffened melt is not shedding them fast enough.

M390 and Coffee clay with G2934 matte glaze at cone 6 fired using our lab C6PLST firing schedule (free fall after cone 6 reached). This demonstrates the need to use the PLC6DS or C6DHSC schedules instead.

Coffee Clay generates gases that can 'puff up' glazes. These two mugs are a refire, left is M390, right is Coffee Clay (notice how the glaze surface on the latter has orange-peeled).

Glazing

Commercial brush-on glazes: They may or may not fit our clays (check for glaze fit using a BWIW test or similar). For brightly colored glazes (especially with layering) do a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

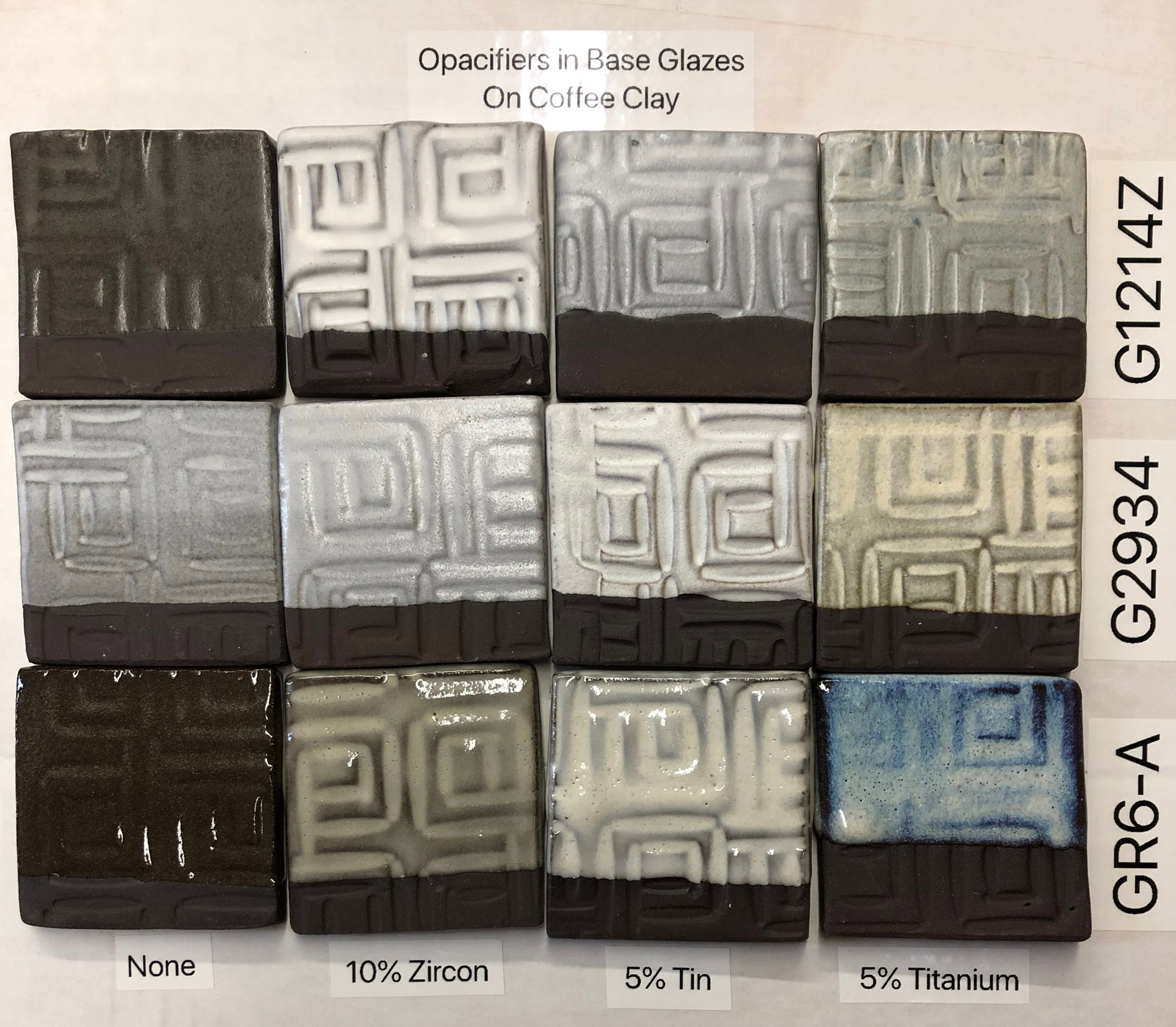

However, base glazes that work on M340 may not work on this because of micro-bubble clouding (e.g. G2926B, G2934 matte). But Alberta Slip and Ravenscrag Slip glazes work well for us. Of course colorants in the body will bleed into glazes, often making them appear quite different than they would on lighter burning bodies.

Crazing: Functional ware must remain craze-free (crazing is unsanitary and drastically reduces ware strength). Even though ware may not be crazed out-of-the kiln it may do so with time. Do cycles of a boiling water:ice water immersions (BWIW test) on a piece to test glaze fit (by stressing it to bring out any crazing or shivering tendencies).

Coffee Clay works well with the standard white version of our L3954B engobe (visible on some of the pictures here). If G2926B crazes over it, consider G2926S.

This body is a great candidate for the engobe process, we recommend the L3954B recipe. It can be colored with stains or whitened with zircopax. It can be applied thickly as an engobe or thinly as a slip.

Caution About Clear Glazes

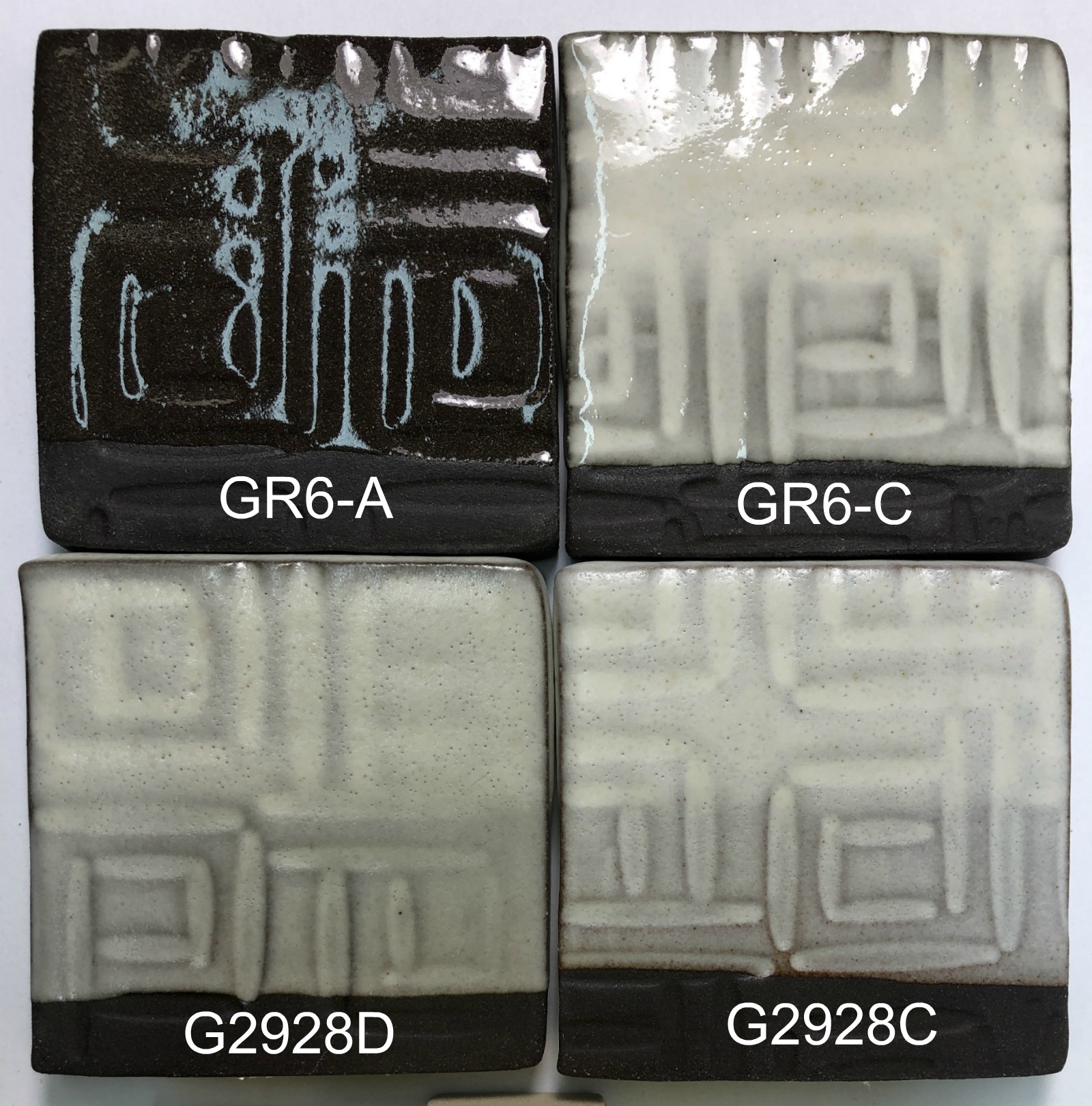

Clear glazes often do not work on our dark burning bodies (like M390, Coffee Clay). The center mug is clear-glazed with G2926B (and is full of bubble clouds).

Left mug: The outside glaze adds 4% iron to G2926B (the iron particles are acting as a bubble fining agent). Right mug: The whole thing is glazed with GA6-B Alberta Slip base glaze.

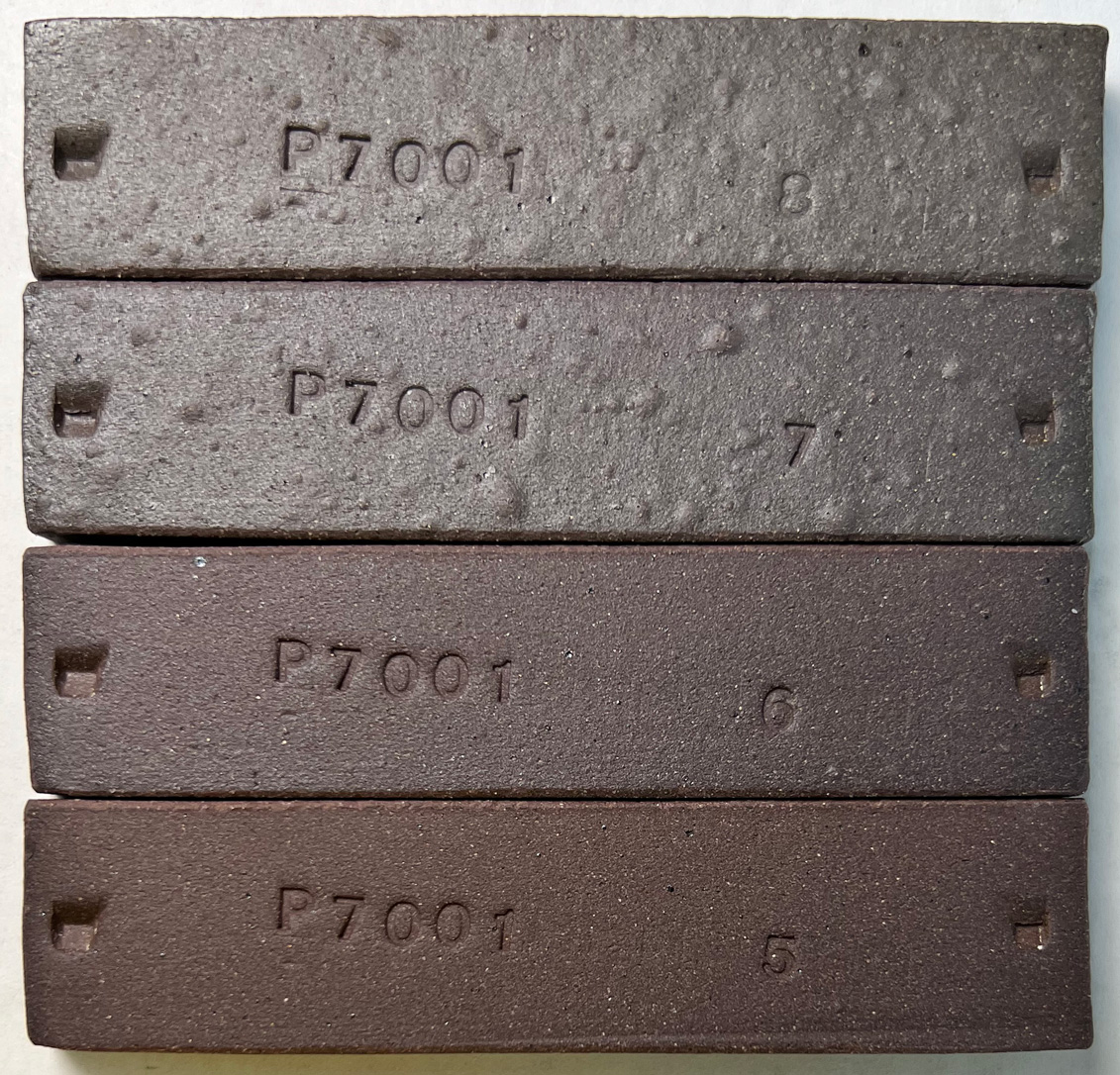

Coffee Clay fits L3954B engobe perfectly. These bi-clay sandwich the body and engobe together, they have dried and fired perfectly flat (neither side has pulled or pushed to curve the bar).

Coffee Clay with Ravenscrag base glossy, white and matte glazes. These were fired using the C6DHSC firing schedule. There are lots of small dimples on the double-thickness sections at the tops.

The raw umber in Coffee clay generates significant gases as firings approach cone 6. With some glazes (e.g. rutile blues) this activity enhances the variegation. But with others, like this white matte, which has a stiffer melt, many pinholes are generated.

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.5-7.0% LOI: 6-7% Water Content: 21.5-22.5% Drying Factor: C120

Sieve Analysis (Tyler mesh):

+48: 0.0-0.1% 48-65: 0.4-0.8 65-100: 1.5-2.5 100-150: 1.5-2.5 150-200: 4.0-6.0

Fired Shrinkage:

Cone 4: 5.5-6.6% Cone 5: 6.0-7.0 Cone 6: 6.5-7.5 Cone 7: 6.0-7.0

Fired Absorption:

Cone 4: 5.0-6.0% Cone 5: 3.0-4.0 Cone 6: 2.0-3.0 Cone 7: 1.0-2.0

Gallery

These Coffee clay mugs have been white L3954B engobed at leather hard stage on the insides (the center one partway down the outside). After bisque the left and right ones were white-glazed on the inside (using G2926B+10 Zircopax). The one on the right has GA6-A (Frit 3195 version) on the outside (the center mug inside and out). The GA6-A over the black clay produces a very deep, rich ultra-gloss surface. The mug on the left has Ravenscrag floating blue (GR6-E) on the outside (producing a very right color over the Coffee clay).

M390 vs. Coffee clay. The upper sections of the mugs are white engobed (using L3954B) under the amber-clear glaze. The glaze is Plainsman Alberta Slip base GA6-A (with Frit 3195).

Left: Coffee clay with L3954B white engobe inside and partway down the outsides. The liner glaze is Plainsman whiteware clear G2926B. Outside glaze is GA6-C Alberta Slip Floating Blue. Right: M340 with black stain replacing the Zircopax in the engobe recipe. It is glazed inside and out with Alberta Slip base GA6-A (using Frit 3195 as the flux).