M340S Old

No longer available. Please use the improved M340S REV instead.

Description

M340S is our pre-2023 M340 speckled body. It had 0.2% added 60-80 mesh granular manganese. No longer produced.

Process Properties

M340S has the same plastic and drying properties as M340.

Firing

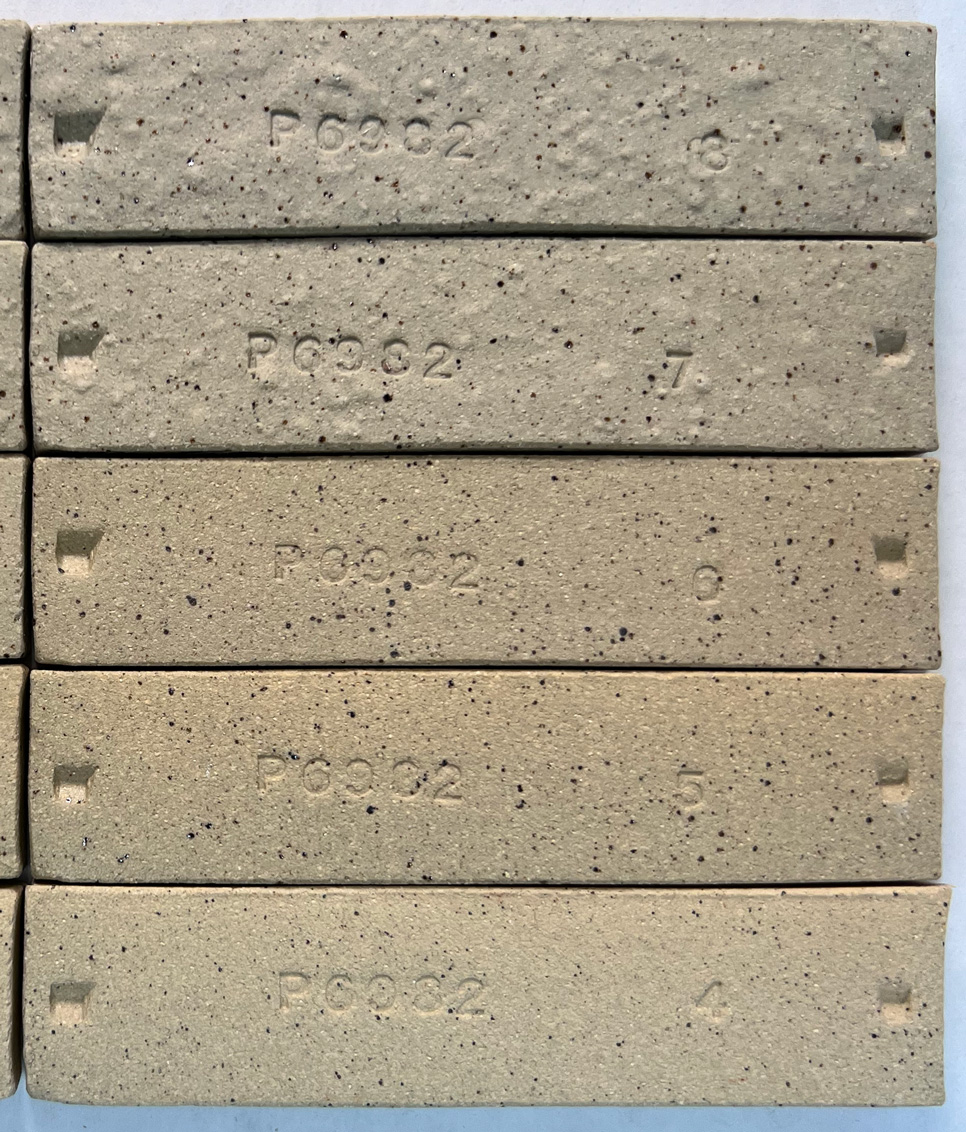

The added manganese produces a fine black speckle that usually bleeds up through glazes. These bodies MUST NOT be fired higher than cone 6 or they will blister, we recommend cone 5. It is possible to get success at cone 6 sometimes, but it is too close to the margin to trust, fire lower. Verify your kiln controller is accurate, then manually program it to finish the firing at the desired temperature. If some parts of your kiln fire hotter, do not put these clays there. Overfiring will result in loss of ware.

To get the best defect-free surface please consider using a drop-and-hold firing schedule, for example the PLC6DS schedule. If crystallization during cooling is not an issue, glazes will give optimum results if slow-cooled also (e.g. the C6DHSC schedule).

Glazing

Toxicity: the vast majority of the manganese particles are encapsulated within the clay matrix. The tiny percentage exposed at the body surface are under the glaze. It is not the manganese particles themselves that expose at the glaze surface. Rather particle surfaces that contact the underside of the glaze bleed out into it from below, doing so as a function of the glaze thickness, opacity and melt fluidity. Thus, food contact with a glass surface having isolated manganese-pigmented regions is not at all the same thing as with raw manganese metal (or a glaze having powdered manganese as a colorant, some have up to 5%).

Physical Properties

Drying Shrinkage: 7.0-7.5% Water Content: 21% Drying Factor: C130

Sieve Analysis (Tyler mesh):

+48: 0.0-0.1% 48-65: 0.5-1.5 65-100: 1.5-2.5 100-150: 2.5-3.5

Fired Shrinkage:

Cone 5: 4.5-5.5 Cone 6: 5.0-6.0 Cone 7: 5.0-6.0

Fired Absorption:

Cone 5: 2.0-3.0 Cone 6: 1.0-2.0 Cone 7: Bloating

Gallery

The body is Plainsman M340S. Cone 6. Left to right: G1214Z calcium matte base glaze with 6% titanium dioxide added. GR6-A Ravenscrag base with 10% zircopax (zircon). G2926B glossy transparent base with 10% zircon. G2934Y silky magnesia matte base with 10% zircon.

Safety Data Sheet

Click here for web view.We Are Rationalizing Our Product Line

Plainsman manufactures bodies by grinding and pugging clays that we mine (native bodies) and by batch mixing bagged minerals and materials that we import (refined bodies). We stock about 10,000 boxes of 50+ clays (some in multiple stiffnesses) and need to reduce the warehousing and production burden of small-run bodies and remove obsolete and legacy products. For bodies being discontinued: We have migration paths and can assist with issues. Some changes involve increased cost. In certain cases you might consider having us custom-mix a body so you can continue to get it, but please work with us on trying to adapt to alternatives first.