Home

Glazes, Engobes

G2916F Transparent Cone 6 Stoneware Glaze

Description

For Stonewares like M340, M325, M390, M350.

This is an industrial tableware glaze recommended by tech support at Fusion Frits. It not only fires hard and crystal clear but has outstanding suspension and application properties. In addition, it works well with most stains.

The magic for the way this glaze fires and its hardness and durability lie in the variety of fluxes in contains and the very low boron content coupled with high SiO2 and Al2O3. The fluxes most likely to create micro-bubbles at this temperature are sourced in a frit. It has the traditional CaO and KNaO, but the talc adds MgO and the frit adds SrO plus a tiny bit of BaO. This mixed-oxide effect produces a very well melting glaze yet having excellent body (considering it has only 18% of a low-boron frit).

Firing

It is standard practice to fire cone 6 using a hold (or soak) at top temperature schedule (e.g. for 30 minutes) to produce a defect-free glaze. However we recommend a drop-and-hold firing schedule (like PLC6DS). Both require manual programming of your kiln (because none of the built-in programs do any kind of hold). If you have not manually programmed your kiln, this is a barrier you need to cross to produce more defect-free glaze surfaces.

Glazing

When mixed with water to create a thixotropic slurry, this will perform was as a dipping glaze. It will apply evenly to bisque, produce minimal dripping and dry within seconds. It will be adequately durable for handling. If bisque walls are thin, it will be necessary to glaze the inside and outside of pieces as separate operations (with a drying time between).

If you are glaze layering (using this as a dipping glaze and painting a commercial gummed brushing glaze over it) there is a risk of crawling. It may be necessary to add some gum to this, converting it from a dipping glaze to a base-coat dipping glaze.

Recipe

The recipe of this glaze is not proprietary. We developed it and sell it premixed but you can batch it (or even adjust it) yourself. For detailed technical information check its page, G2916F, at the Digitalfire Reference Library.

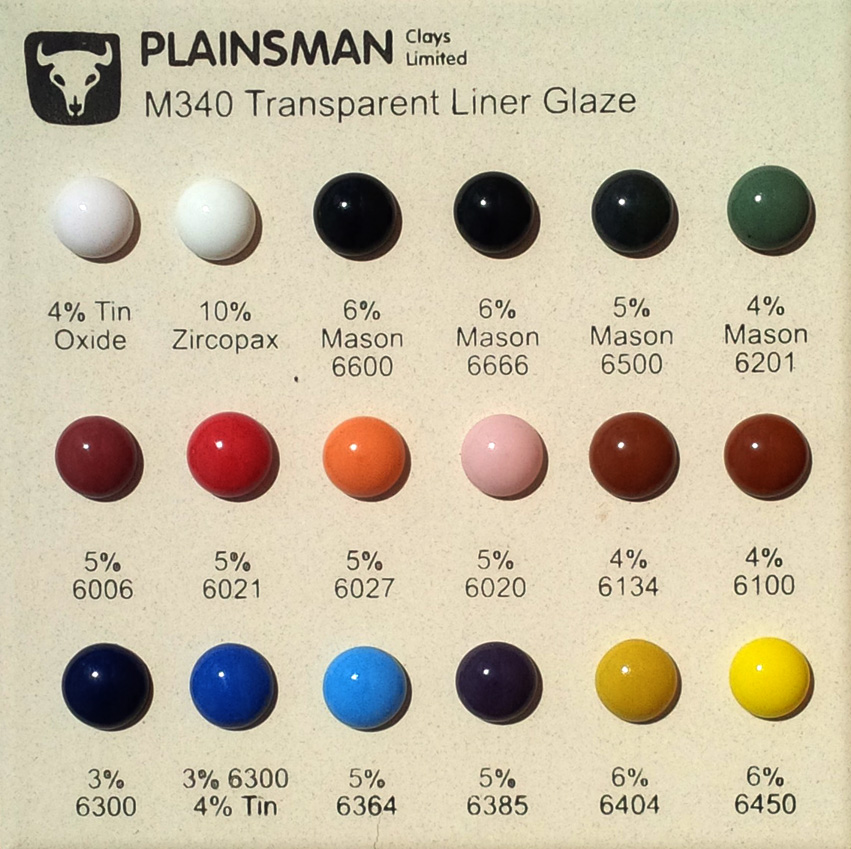

Adding the Stains and Opacifiers: Simply multiply the weight of the amount of powder you want to use and divide by 100. For example, if you have 2000 grams of glaze powder and want to add 6% stain: 2000*6/100=120 grams of stain. Or, 10% zircopax: 2000*10/100=200 grams of zircopax (stain %'s are suggestions, for some colors you may need more, testing is needed). Bright colors and whites will be muted on dark-burning bodies.

For darker firing bodies like M390, we recommend using the GA6A base Alberta Slip glaze.

Mixing Instructions

If you just want to mix it the traditional way, start with equal weights of water:powder and mix well using a propeller mixer. Add more water until it is creamy, try it, adjust, etc. To learn more visit the G2916F page at the Digitalfire Reference Library.

If you want better application properties (as a one-coat dipping glaze) we recommend targeting a specific gravity of 1.5 and gelling the slurry to make it thixotropic (see next paragraph). Water amount: Total weight of powder x 1.05. Yield: 1.2 litres per kg of dry powder.

To prepare for use as a single layer dipping glaze, add the powder to 95% of the water and mix well. Then add water as needed to get the right specific gravity. To break up agglomerates sieve through 80 mesh or blender mix the slurry. The best dipping results come with a ~1.44 specific gravity thixotropic slurry that gels and holds itself in place after dipping (this "rheological state" can change on storage so be ready to adjust it later).

This can also be mixed as a brushing glaze or a base-coat dipping glaze.