Home

Glazes, Engobes

G2934 Cone 6 Matte Base Glaze

Description

For Stonewares and Porcelains. We document procedures to mix this as a brushing glaze, dipping glaze or base coat dipping glaze.

A dolomite silky matte for cone 6. It fires translucent rather than completely transparent. For pure white, add Zircopax (start with 5%, but keep it at a minimum to minimize cutlery marking and crawling). Digitalfire.com has more information, including recipe, on G2934.

G2934 Cone 6 Matte base (upper left sample) with various stain additions. A porcelain body, M370, has been used (bright colors do not work on dark burning bodies unless you underlay them with an engobe). Mason 6020 is a body stain, it does not work in glazes (as you can see here). Mason 6006 also does not work (because this glaze does not have enough CaO in the chemistry).

Firing

Matte surfaces are delicate and difficult to maintain consistency. First, the degree-of-matteness is very dependent on cooling rate. Fast cooling (e.g. free-fall in a lightly-loaded or smaller kiln) produces our desired silky matte surface. Slow cooling (e.g. a heavily loaded kiln) produces a more matte and drier surface (subject to cutlery marking or staining). Do test firings to determine if you can adapt your firing to this recipe or need to adapt this recipe to your firing. If the latter, blend in some glossy G2926B to shine it up to the degree needed (e.g. a 90:10 mix of matte:glossy).

It is standard practice to fire cone 6 using a hold (or soak) at top temperature schedule (e.g. for 30 minutes) to produce a defect-free glaze. However, we recommend the drop-and-hold PLC6DS firing schedule. Both require manual programming of your kiln (because none of the built-in programs do any kind of hold). If you have not manually programmed your kiln, this is a barrier you need to cross to produce more defect-free glaze surfaces, especially with matte glazes.

This glaze will likely fire too matte at cone 5. The G2934Y variation has the same chemistry, but because it employs more frit and melts a little better it might be more suitable.

G2934 works particularly well with inclusion stains, producing bright colors. Bright colors quickly reveal even slight differences in the degree of matteness. Each stain will affect it differently, so adjust as noted above, by mixing with G2926B glossy.

G2934 works quite well as a transparent overglaze (for tissue transfers and underglaze decoration). If it is too matte, shine it up to the degree needed, as noted above, by blending in some clear glossy G2926B.

There is nothing intrinsically toxic in the recipe, so by itself it is not a leaching hazard. But additions of metallic colorants will change that, consider doing a GLLE test to verify (it is generally best not to employ glazes having high percentages of metal oxide colorants on food surfaces).

Speed of cooling affect the mattness of G2934. Top: Drop-and-hold PLC6DS schedule. Bottom: Drop-and-hold and slow-cool C6DHSC firing. Note that the slow-cool version is much more opaque (important if been used over underglaze decoration).

You can tune the degree of matteness of G2934, just blend in some glossy. Far left: Pure G2934. Top row proceeding right: 10%, 20%, 30%, 40% G2926B added (100% G2926B far right). Bottom: G2916F in the same proportions.

G2934 matte glaze fired at cone 7 on Plainsman M370, P300 and M340. Standard drop-and-hold PLC6DS (not a slow cool).

M390 and Coffee clay with G2934 matte glaze at cone 6 fired using our lab C6PLST firing schedule (free fall after cone 6 reached). This demonstrates the need to use the PLC6DS or C6DHSC schedules instead.

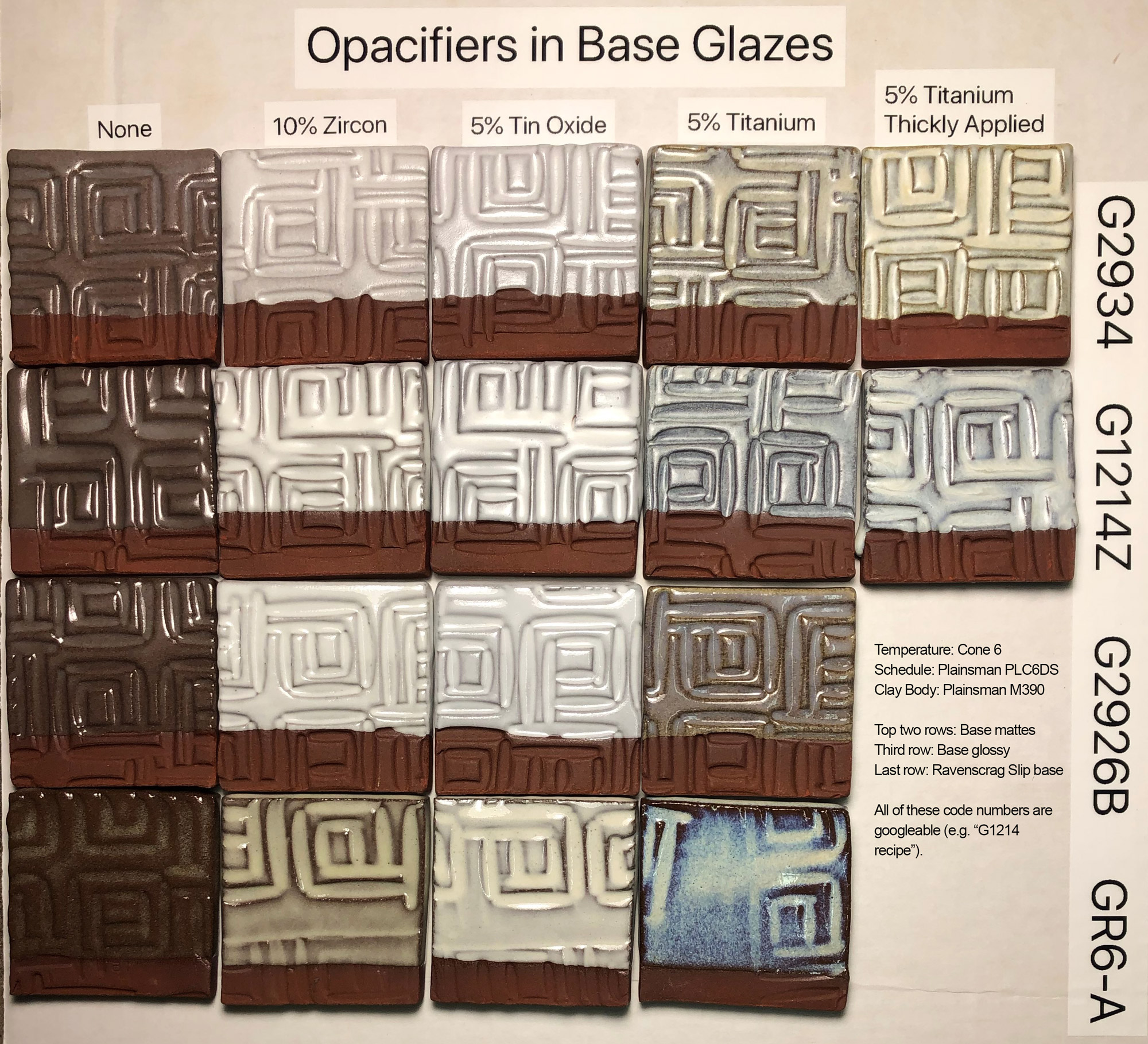

The body is Plainsman M390. These are commonly used base glazes. The top one is an MgO matte, the next is a calcium matte. They behave very differently to these additions. Notice also that thickly applied titanium dioxide is very different. Tin oxide fires whiter than zircon (e.g. Zircopax). Also, zircon opacified glazes tend to crawl so special precautions may be needed.

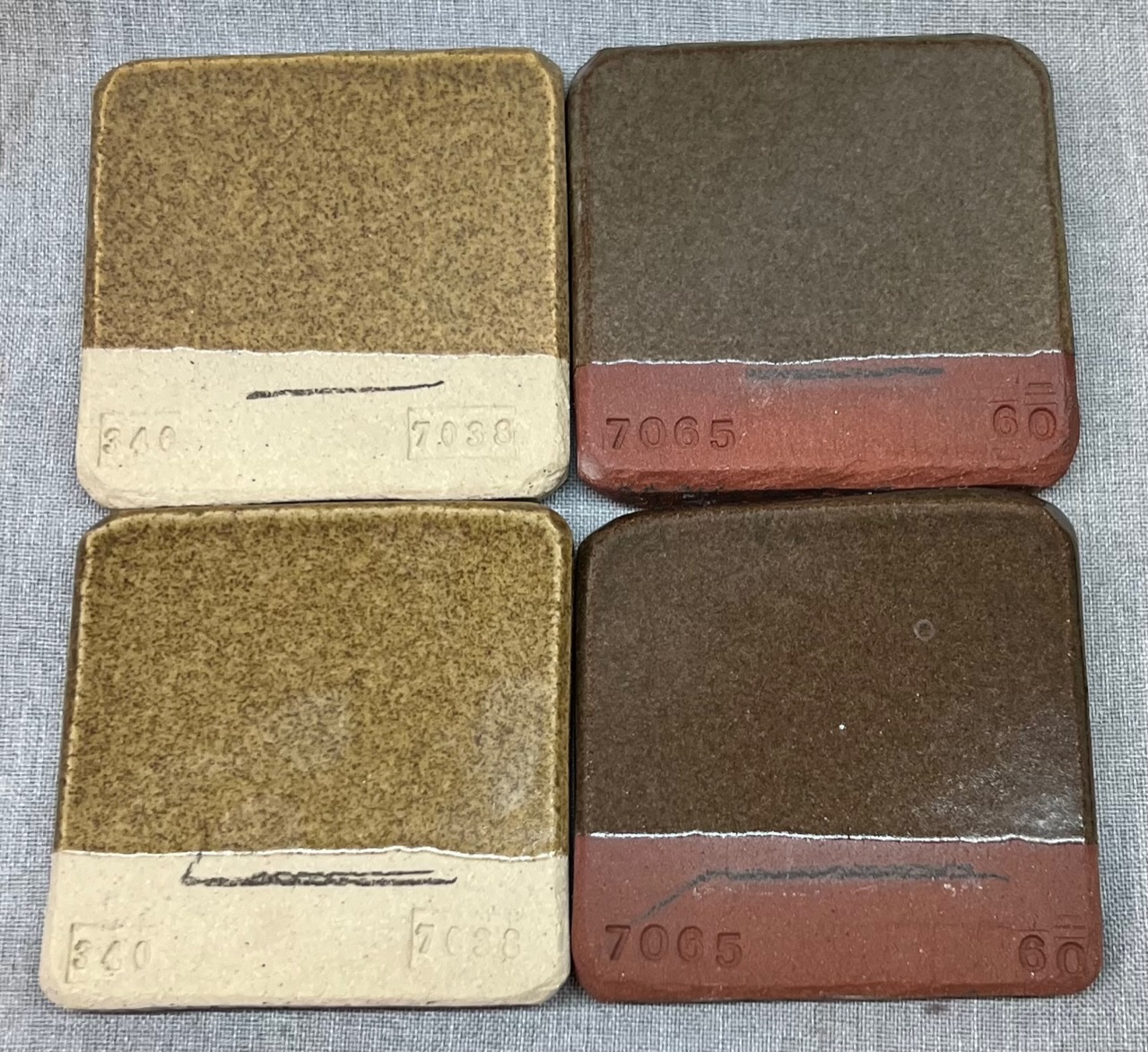

G2934 matte glaze + 4% iron oxide on M340 and M390. The top two are cone 6 slow cool firing C6DHSC and the bottom two are the PLC6DS schedule (the result is the same).

Glazing

When mixed with water to create a thixotropic slurry, this will perform well as a dipping glaze. It will apply evenly to bisque, produce minimal dripping and dry within seconds. It will be adequately durable for handling. If bisque walls are thin, it will be necessary to glaze the inside and outside of pieces as separate operations (with a drying time between).

Glaze Fit: This glaze recipe has a low thermal expansion. That means it will fit, without danger of crazing, on anybody we make. However, under some circumstances, it could shiver. If this happens, consider using the G2934Y2 variation, it has a higher thermal expansion (as noted above if it is too matte blend in some glossy G2926B).

Opacity: The slower the cool during firing the more opaque this glaze will fire.

G2934 matte can crawl if applied too thick. These are M370 (normal thickness left, too thick right).

If you are glaze layering (using this as a dipping glaze and painting a commercial gummed brushing glaze over it) there is a risk of crawling. It may be necessary to add some gum to this, converting it from a dipping glaze to a base-coat dipping glaze.

Recipe

The recipe of this glaze is not proprietary, it is code numbered G2934. We developed it and sell it premixed but you can batch it or its variations or even adjust them yourself. Variations include G2934Y1 - G2934Y4). Information pages on these recipes describe how to adjust the recipe for more or less matteness. For less matteness use the strategy described above (blending in some glossy). For more matteness cooling the kiln slower or fire to cone 5 will also work.

Adding the Stains and Opacifiers: Simply multiply the weight of the amount of powder you want to use and divide by 100. For example, if you have 2000 grams of glaze powder and want to add 6% stain: 2000*6/100=120 grams of stain. Or, 10% zircopax: 2000*10/100=200 grams of zircopax (stain %'s are suggestions, for some colors you may need more, testing is needed). Bright colors and whites will be muted on dark-burning bodies.

Recipe adjustments: Starting with the #6975 run of Sept 2022 we began using 325 mesh silica (giving a more functional surface).

Mixing Instructions

To mix this as a traditional single coat dipping glaze, start with equal parts water and powder (by weight) and mix well using a propeller mixer (this page previously had an error here, it said 85:100 water:powder). For us, this produces a specific gravity of around 1.45 (with some rood to add a little more water), a creamy consistency yielding about 1.4 litres per kg of dry powder. Since the recipe contains plenty of clay it usually suspends and applies pretty well as is.

The high clay content has a downside: Glaze crawling with certain stains and opacifiers. Any cracking that appears as the glaze dries is a warning of possible crawling (e.g. at sharp concave angles or double-dips). Optimizing the thixotropy of the slurry produces a more even laydown that is less likely to give issues. Test in your circumstances before making large batches or glazing high volumes are ware.

To prepare for use as a single layer dipping glaze, add the powder to 95% of the water and mix well. Then add water as needed to get the right specific gravity. To break up agglomerates sieve through 80 mesh or blender mix the slurry. The best dipping results come with a ~1.44 specific gravity thixotropic slurry that gels and holds itself in place after dipping (this "rheological state" can change on storage so be ready to adjust it later).

This can also be mixed as a brushing glaze or a base-coat dipping glaze.

Gallery

G3933A oatmeal glaze (the G2934 base plus iron, tin and rutile) fired using the C6DHSC drop-and-hold slow-cool firing schedule. The clay is Plainsman M390. Note: We are now recommending the Ravenscrag Slip based version of this, G3933EF.

12% yellow and 8% orange stains in G2934 base recipe. The silky surface of these is outstanding! It depends on the PLC6DS firing schedule.

The body is Plainsman M340S. Cone 6. Left to right: G1214Z calcium matte base glaze with 6% titanium dioxide added. GR6-A Ravenscrag base with 10% zircopax (zircon). G2926B glossy transparent base with 10% zircon. G2934Y silky magnesia matte base with 10% zircon.

G2934 with yellow stain (left) vs. a glossy glaze (G2931K with the same yellow stain but fired at cone 03). The matte surface is much easier on the eyes for bright colors (and much more pleasant to the touch).

Right pail: 2 gallons of G2934 base with 10% Cerdec yellow stain. Cost: $135. Jars with the same amount: Almost $300! And you have to paint them on in three coats with drying in between. The one in the pail is a true dipping glaze. You can dip a bisque mug for 2 seconds and it dries immediately in a perfectly even layer (if mixed according to our instructions).

G2934 Black with Amaco PC-32 brushed over it. Fired at cone 6 on buff stoneware. PLC6DS firing schedule.

Handmade mugs by Tony Hansen. G2934Y glaze with stains on P300 and Polar Ice. PLC6DS firing schedule.

M370 casting bowl with sprayed Amaco underglaze banding and G2934 matte base cover. Fired at cone 6.